Main technologies that allow you the 3D scanning of industrial parts

3D scanning systems give us another perspective, an overview of the parts to analyze and much more information than you could get so far with conventional contact measurement methods.

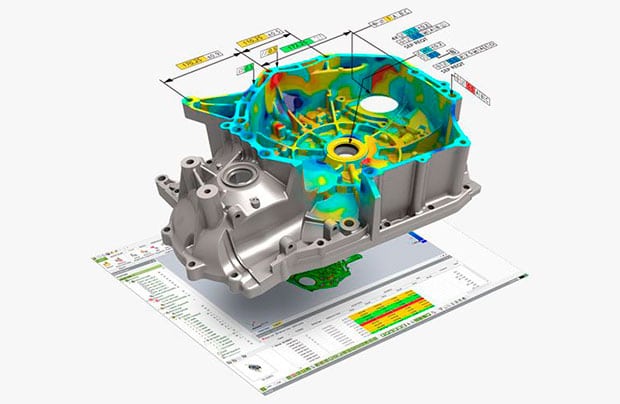

When you get the digital copy of your part, you have many options: perform a quality control comparing your capture with the nominal CAD and thus see the errors, analyze structural and functional defects, perform reverse engineering or 3D printing.

The greatest benefit that 3D scanning systems give us is all the information they give us in a simple and very visual way.

At a glance we can see if our part is OK or NOT OK in terms of shape (surface). We can save all this digital information for future work. For example, to modify a part starting from an old one and manufacture it or for example when we have a non-conformity from a customer, we can review aspects that have not been critical at first, but that require a later evaluation.

At Sariki we have a wide variety of technologies that adapt to all industrial needs (accuracy, part size, automation options ...). Here, we show you what these technologies are:

3D laser scanner

3D laser scanner technology can be integrated into both CMM machines, portable arms and robots depending on the requirements of the part/process.

You can measure practically any material, including machined, semi-finished, stamped, forged, cast, painted metals, sand cores, carbon fiber, plastics, clay, rubber, wood, and ceramics.

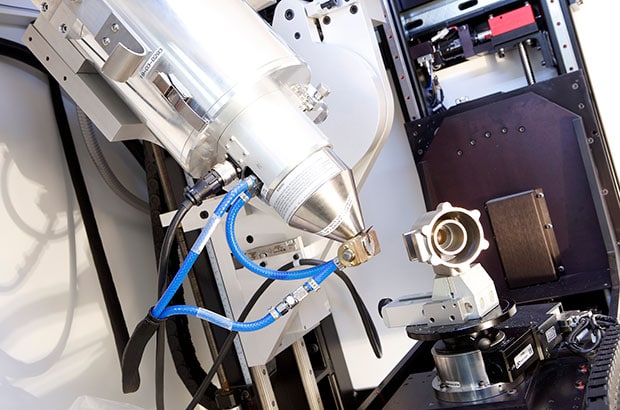

3D laser scanner on CMM

Increase the productivity of the measurement process by acquiring more information in less time. In addition, you have the ability to automate the measurement process combining both contact probes, continuous measurement, roughness, vision and laser scanner. Incorporating different technologies into a CMM offers you many advantages.

Interesting for those companies that need a complete validation of the part they manufacture, have to verify many geometric and surface characteristics, and want to optimize the process.

3D laser scanner on portable arm

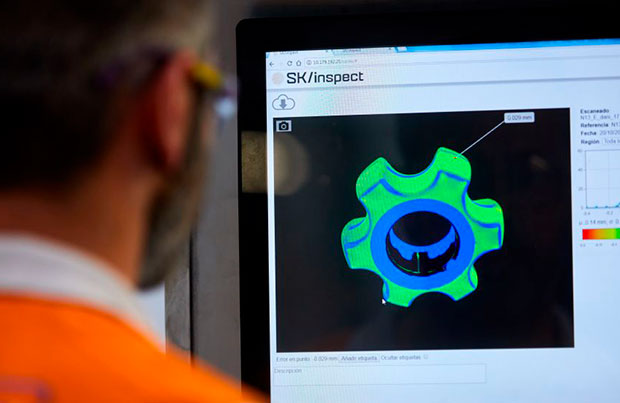

It allows you to quickly capture the digital copy of your part and evaluate the surface in a very visual way.

Interesting for those measurement tasks that require portability and flexibility. It enables action to be taken directly in the manufacturing environment, where process improvements are most beneficial.

Different models of laser scanner are available depending on the required line resolution and accuracy.

3D laser scanner on robot

It allows robotization and automation of the inspection through the integration of a 3D laser scanner in a flexible multi-axis robot. It offers an automated 3D measurement experience, from planning and capture to analysis and reporting.

Interesting for those companies that require non-contact, fast and efficient quality control within the production line. The generated data can be easily integrated into the workflow.

Structured light

The structured light technology allows the complete automation of the 3D scanning process, as well as its integration into the robot.

Different equipment available depending on the size of the part and required resolution.

Desktop structured light

It enables users to enjoy a quick and easy metrology experience. Position the object and start scanning with one click. In addition, it does not require targets or manual alignments, thus allowing the capture, analysis and reporting process to be fully automated.

Interesting technology to digitize industrial parts and jewelry.

Structured light on robot

The robot allows you to automate the processes, at the same time the scanner with the structured light technique gets a point cloud which picks up all the information of the produced parts.

This solution is suitable for measuring, processing and obtaining the more information possible in the fastest way, mainly for automated processes with high cadence of parts. It is oriented toward inline measurements.

The data generated can be easily integrated into the workflow.

Computed tomography

Industrial tomography can help you your part quickly and non-destructively, with a complete internal and external inspection.

Computed tomography (CT) is basically a non-destructive process in which images (radiographs) are captured from all directions by penetrating radiation and subsequently allows the reconstruction of a 3D volume of the component, based on the intensity values of the projected images. Using advanced analysis software, the presence of pores or internal defects can be detected, as well as the measurement of inaccessible internal dimensional characteristics.

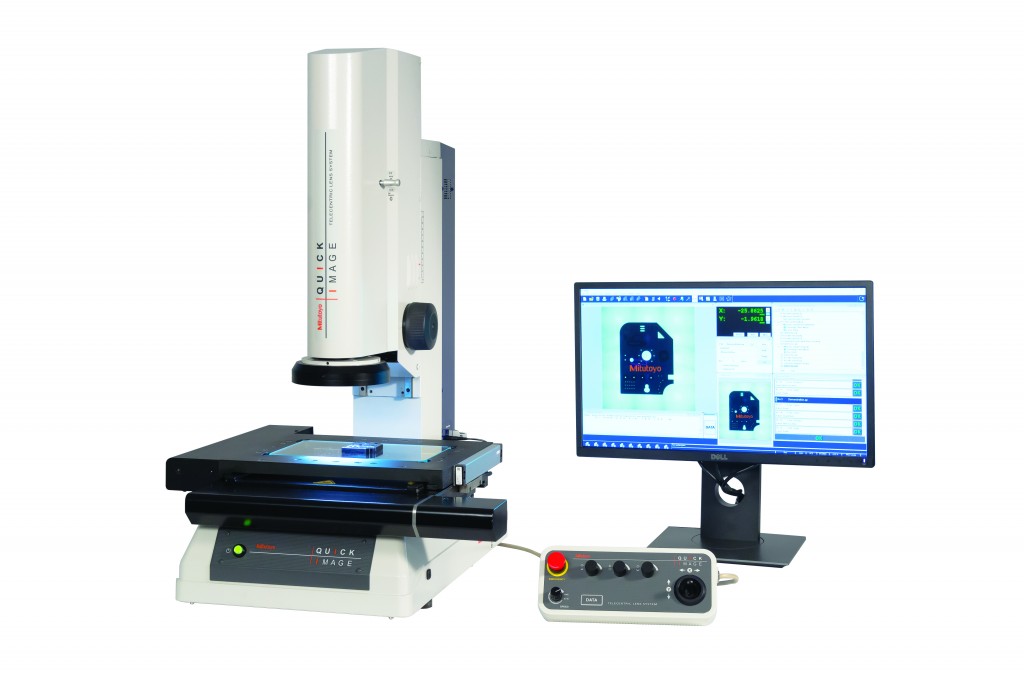

Vision

The optical measurement of parts allows to automatically adjust the illumination and focus of the lenses during the inspection process, thus eliminating the operator's influence.

In addition, it allows the automation of dimensional control in production.

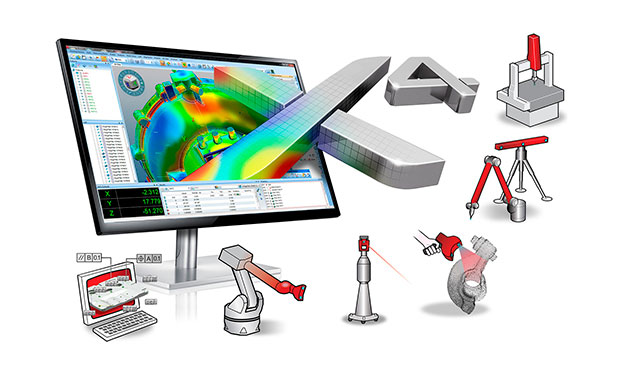

Software

There are different softwares on the market that are used with all these 3D scanning technologies.

At Sariki we can advise you and help you choose which technology is best suited to your needs. You can call us at 943848889 or fill out the following contact form.