Structured light scanner

We propose you a contactless inspection solution that will allow you to obtain a digital copy of your parts so that you can later make:

- quality control comparing your measurements with the nominal CAD and thus see the errors

- analysis of structural and functional defects

- reverse engineering

- 3d printing

Sariki is POLYRIX'S official distributor for Spain and Portugal

With the blue LED structured light you will get better results

Structured light scanning is a comprehensive term that includes all colors of light but generally refers to white or blue light. The way structured light scanning works is you project a structured light pattern onto an object and film it, usually using two cameras (need at least one). The cameras capture how the object deforms the light. Doing this, you can calculate the dimensions of the object, resulting in a 3D image.

Structured light is used as an alternative to 3D laser scanning. While laser scanning has its positive aspects, lasers are easily disrupted by reflected surfaces, any form of transparency, or even complex interference patterns in the laser light.

The object is scanned at different angles

Structured light is known for its accuracy. The object being scanned, such as jewelry or a helmet, remains stationary. The scanner then projects various patterns of light onto the object, recovering data based on how the light is deformed. High accuracy is, in large part, due to the object being scanned at different angles. The set-up is also very simple. After placing the object in the scanner and inputting the light exposure and analysis settings, you are ready to scan. Structured light scanners are also very safe as there is no focused light (as is the case with a laser), therefore eye safety concerns are not a factor when using white or blue light.

In the past, white was preferred for structured light scanning. However, sophisticated LEDs have changed the new standard to blue light thanks to its increased accuracy and higher resistance to disruptive forces. Due to LEDs, blue light scans are less sensitive to heat than white light scans. This is important because it means that the light source is more consistent and can run longer.

For slightly transparent and shiny objects blue light is superior. The projected fringes are easier to read through blue light because blue light, having short wavelengths, is not transmitted and reflected from the surface.

Integral project adapted to your needs

We offer an integral solution, adapted to your needs. The experience tells us that the collaboration with the client is the basis of success in this type of projects and that is the reason why we work jointly from the beginning, to identify which are the principal requirements and suggest the best solution.

We accompany you throughout the life of the project: project definition, installation, training, programming, user support and technical assistance. Sariki is made up of 60 highly specialized people with more than 35 years of experience in the metrology sector.

We accompany you throughout the project life

Get to know our structured light solutions

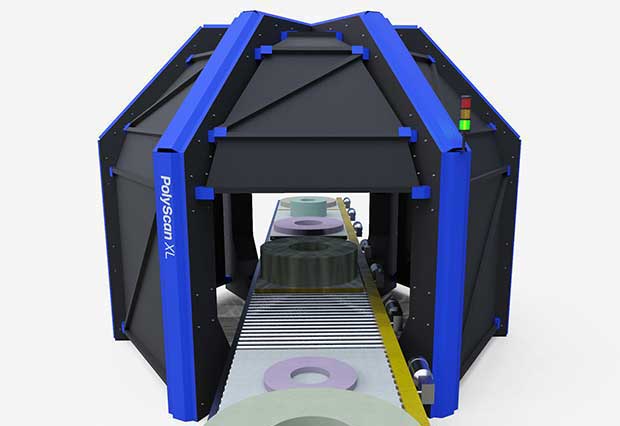

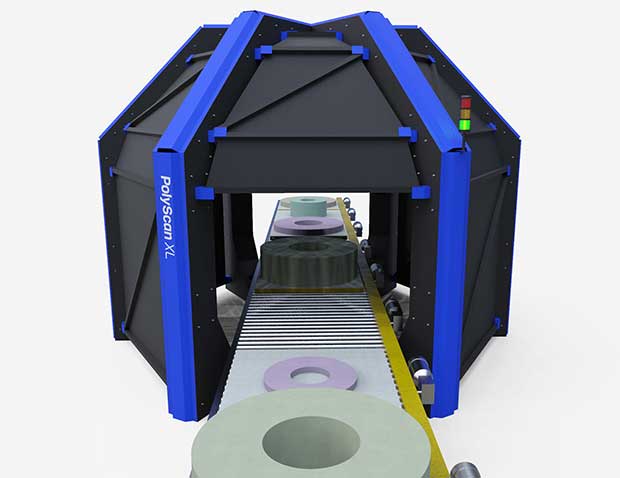

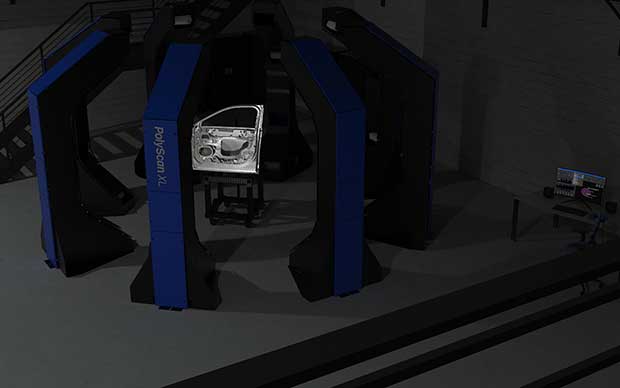

PolyScan™ surround 3D scanner scan large scale objects up to 6500mm. Scanning is fully automated and can be easily integrated in process.