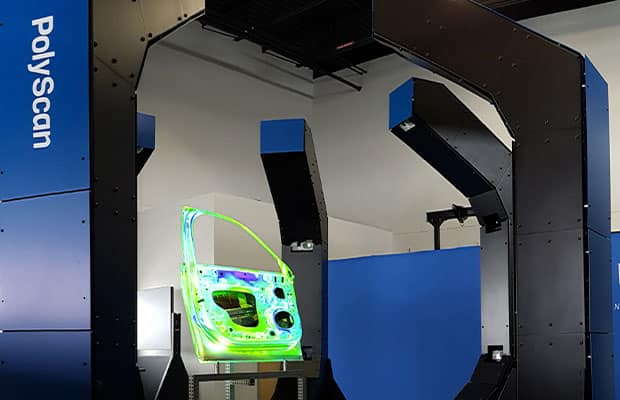

3D scanning

3D scanning systems give us another perspective, an overview of the parts to analyze and much more information than you could get so far with conventional contact measurement methods.

When you get the digital copy of your part, you have many options: perform a quality control comparing your capture with the nominal CAD and thus see the errors, analyze structural and functional defects, perform reverse engineering or 3D printing.

The greatest benefit that 3D scanning systems give us is all the information they give us in a simple and very visual way.

At a glance we can see if our part is OK or NOT OK in terms of shape (surface). We can save all this digital information for future work. For example, to modify a part starting from an old one and manufacture it or for example when we have a non-conformity from a customer, we can review aspects that have not been critical at first, but that require a later evaluation.

At Sariki we have a wide variety of technologies that adapt to all industrial needs (accuracy, part size, automation options ...).

Here, we give you all the information about available equipment.

3D laser scanner

3D laser scanner for portable arm

Structured light scanner