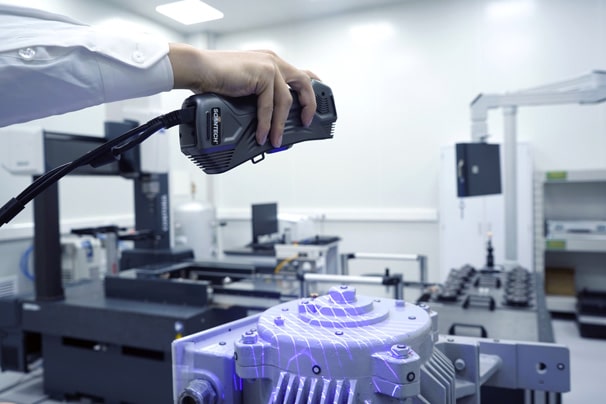

3D laser scanner

We propose you a contactless inspection solution that will allow you to obtain a digital copy of your parts so that you can later make:

- Quality control comparing your measurements with the nominal CAD and thus see the errors

- Analysis of structural and functional defects

- Reverse engineering

- 3d printing

Sariki is SCANTECH'S official distributor for Spain and Portugal

3D laser scanner: Revolutionizing the capture of objects in three dimensions

3D laser scanners have revolutionized the way we capture and represent objects in three dimensions. These advanced tools use laser technology to precisely capture the shape and structure of objects, creating three-dimensional digital models with professional fidelity.

There is a very wide range of 3D scanners on the market: sizes, prices, capacities... and the choice can be complicated. We recommend you to choose the most suitable scanner for your needs, a trusted company with qualified personnel to give you support and can answer all your questions. At Sariki we offer you all the guarantees and a wide variety of technologies.

How do 3D laser scanners work?

3D laser scanners use a combination of lasers and sensors to capture information about an object's geometry and texture. The process begins by projecting a laser beam onto the surface of the object to be scanned. As the laser travels, sensors pick up the reflected light, recording the distance and angle of each point on the object. This data is used to build a point cloud, which represents the three-dimensional shape of the object with high precision. Point clouds are millions of precisely measured XYZ points that define the object's position in space.

Once the scanning process is complete, there is the option to download the model as a point cloud, or to convert it into a triangulated mesh, which can be transformed into a CAD model or a full-color 3D model if it supports texture registration.

What are the factors to consider when choosing a 3D scanner?

Sizes of Objects & Scanning Area

You need to first think about the size of the object you want to scan. If you’re going to scan a small coin, a short-range 3D scanner that can capture intricate details in high resolution would be good. If you plan to scan a large size object or part like a wind turbine, you need a long-range scanner with a larger field of view (scanning area).

Accuracy

The accuracy of the scanning means the permissible deviation of each point captured. Generally, the accuracy of 3D scanners is within a range of 0.01 mm to 0.1 mm. It would be acceptable for most tasks to use a 3D scanner with an accuracy of 0.06-0.07 mm. If you plan to scan a complex industrial part such as an airplane engine, choose a 3D scanner with high accuracy.

Scanning Rate

When we talk about the scanning rate, we refer to how fast a 3D scanner can capture data off any given object. The rate varies depending on the number of laser lines, the size of the scanning area, and the algorithm of the equipment. A top-of-the-range handheld scanner can measure up to 2 million times per second.

Resolution

Resolution describes the minimum distance between captured points at a given scan distance. The higher the resolution, the denser the cloud of scan points. When the details of a 3D model are essential to you, you would require a high resolution. If not, low-resolution requirements are suitable for you.

Integral project adapted to your needs

We offer an integral solution, adapted to your needs. The experience tells us that the collaboration with the client is the basis of success in this type of projects and that is the reason why we work jointly from the beginning, to identify which are the principal requirements and suggest the best solution.

We accompany you throughout the life of the project: project definition, installation, training, programming, user support and technical assistance. Sariki is made up of 60 highly specialized people with more than 35 years of experience in the metrology sector.

We accompany you throughout the project life

Get to know our 3D laser scanner solutions

SIMSCAN, a palm-sized portable 3D scanner, is specially designed for 3D scanning narrow and hard-to-reach areas.

Portability at high speed

The KSCAN-Magic integrated 3D scanner is the world's first scanner that combines infrared laser and blue laser technology for the first time.

Ultra-high precision 3D scanner

The AXE-B17 3D scanner features a built-in global initiative photogrammetry system that provides metrology-grade measurement accuracy and large-area scanning.

TrackScan-P can accurately measure parts without having to stick reference targets.

Ideal for scanning large objects

AM-DESK is an automated 3D measuring station consisting of an intelligent control system, various servo mechanisms, a security system, and a motion control system.

AutoScan-K, is an automatic 3D inspection system, which performs online batch scanning ensuring high accuracy. Designed for automated quality control application

AutoScan-T42 is specially designed for automated quality control in shop-floor conditions, facilitating enterprises to achieve the optimum matching between cost and efficiency.