SK/inspect

Time is a key element in productive processes, and nowadays it is key to inspect 100% to ensure optimum quality to your clients. But the actual measurement solutions require advanced measurement knowledge, that are not usually the most common in the production line’s plant.

Therefore, Sariki offers you an ideal solution to fulfill your needs, a fast and intuitive software for any worker to be able to scan in 3D and analyze produced parts day a day, increasing the productivity and improving the efficiency of your productive processes.

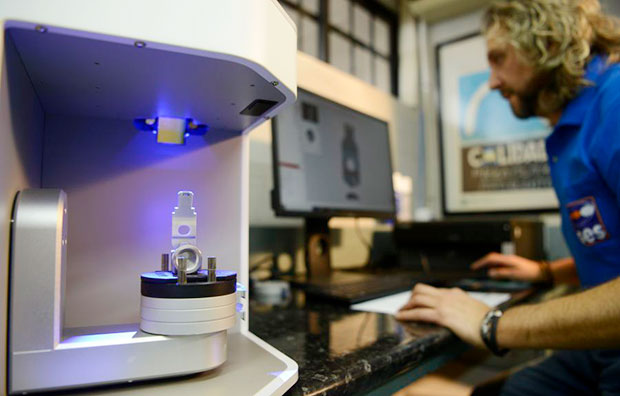

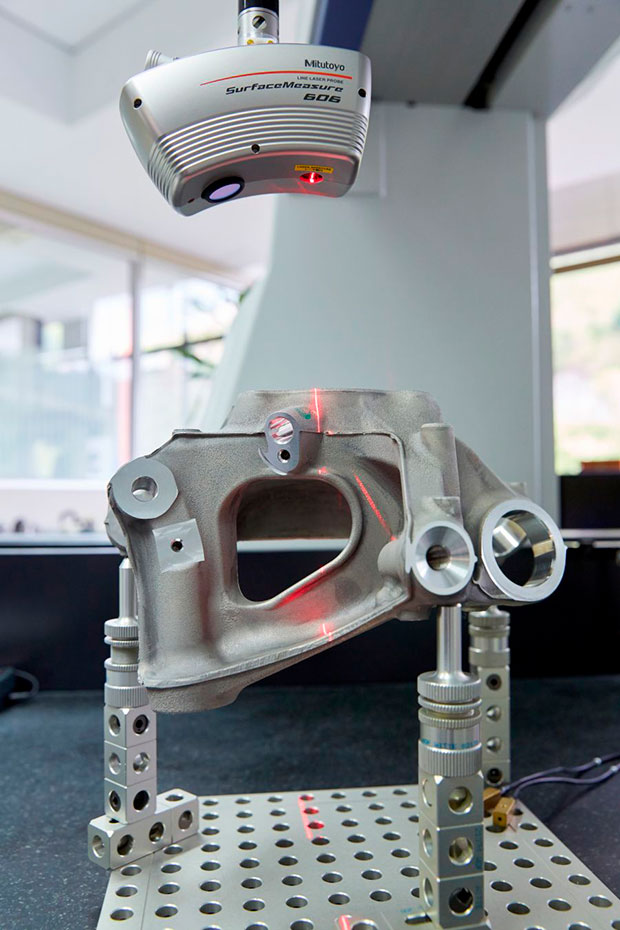

SK/Inspect processes any laser or structured light scanner’s 3D point clouds. The point clouds captured by any hardware that you have selected are processed in the production plant and the results are shown in color mapping format. Obtained datum are sent to a database in the cloud, in where any department of any plant, could access through a 3D web viewer using any standard web browser.

The application provides three different tools:

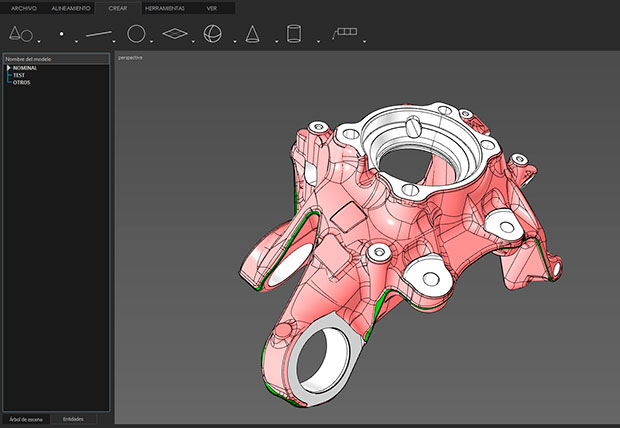

1 PLANNER

Tool directed towards the metrology expert for defining the measurement

This tool is designed to specify the alignment and tolerance procedure parameters of each reference model. The alignment is carried out by specifying a set of 3D primitives (plans, spheres, etc.) that approximate to some relevant regions of the CAD model. These primitives are used to register or align the entry point cloud with the CAD model in the same reference framework. In this way, the alignment is optimal for fulfilling with the functional requirements of the part.

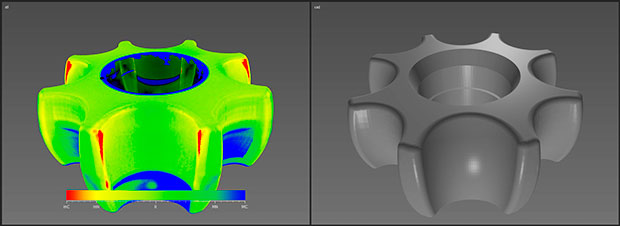

2 INSPECT

Tool directed towards the production worker for measuring

This tool executes the inspection process and carries out the comparison between the point cloud and the reference CAD model. It has been designed to work in the productive plant in an autonomous way, without the need of human intervention. This way, the tool is supervising constantly the scanner, and initiates the inspection process in an automatic way as soon as the new datum is available.

During this comparison process, the point cloud is processing sequentially in this way:

- Delete external elements.

- Alignment.

- Primitives’ adjustment.

- Comparison.

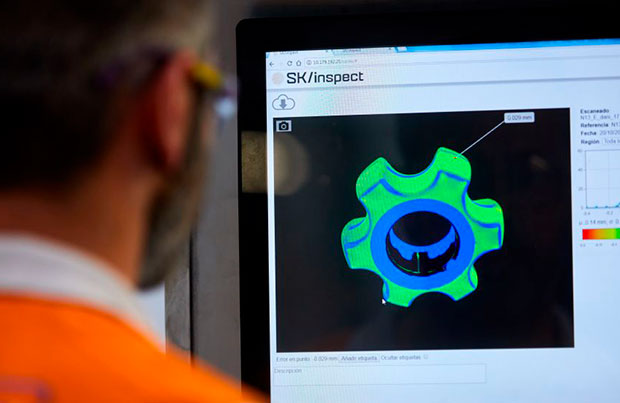

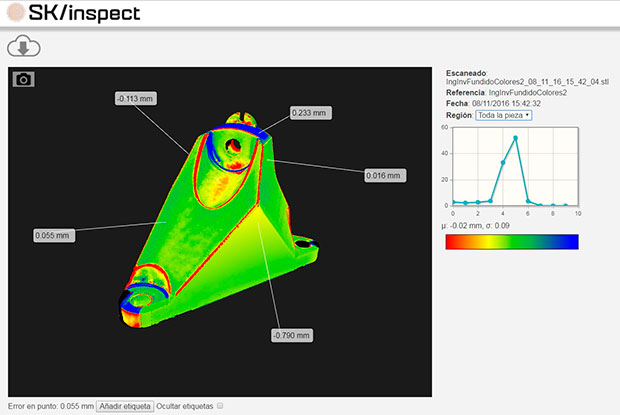

3 VIEWER

Web display tool directed towards the quality department

Every resultant data of the measurement is collected in a server for their remote display. Engineers and metrology experts who want to control the quality of the produced parts could access to a centralized website and inspect the results in an interactive way. If necessary, the users could also create a report for the inspected part.

The web display screen shows the user a list of available scanned parts.

- The new results of the explorations are shown immediately in a remote way.

- The list could be filtered by exploration date and/or by CAD model of reference.

- After the selection of an exploration, the corresponding part is uploaded and displayed in 3D by color mapping.

- Some metadata is also shown, including a histogram of the dimensional error values of the hole part.

The 3D viewer has these functions:

- Manageable interactive view.

- Error inspection.

- Tickets.

- Images’ capture.

Vicomtech-IK4 has collaborated in the development of SK/Inspect and integrated their SDK Geomlib, of high-performance geometrical processing designed for industrial applications.

Applications

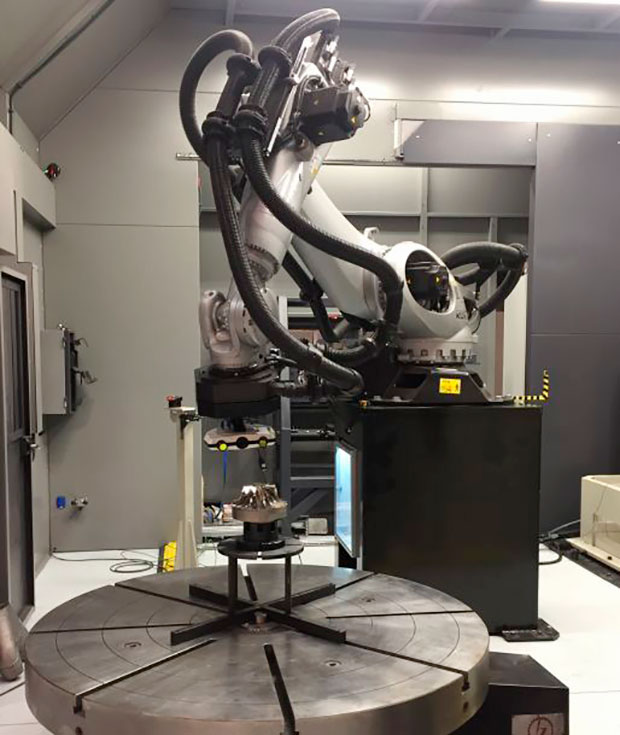

SK/Inspect is directed to fulfill the needs of any industrial sector in which measuring scanners are used (portable or fixed) for the quality control of the production. Specially for manufacturing environment and processes where high-speed processing is required. SK/Inpect provides real time datum of the parts’ state and helps in the decision making of the production process.

Custom Solution

Sariki has bet for developing and applying own solution in the industrial environment of the metrology. SK/Inspect has been developed in an open way to solve your complex challenges yet to be covered, being able to be adapted to your specific needs of each case, and thus personalize the solution for your optimal efficiency.

Main added value of this solution:

- Data flow integrable in a connected intelligent factory.

- Allows the implementation of advanced analytic tools using big data techniques.

- Automate processes.

- Integrable in any hardware.

- Interaction with manufacturing execution systems (MES).

- Guarantee of the traceability of the processes.

- Allows analyzing obtained datum for production’s profit.

- Customized interface.

Technical Specifications

Compatibility with any standard hardware of the sector

High speed to work in manufacturing environment. 5 times faster than commercial products

Completely automated inspection process

CAD formats you could import: IGES, STEP, STL.

Alignment types: N points, Bestfit, GD&T, RPS

Includes simple and intuitive tools for the edition of polygonal meshes

You could identify regions with different tolerances in the CAD

Accessibility of the data from any mobile device