SK/cell

In process 3D scanning

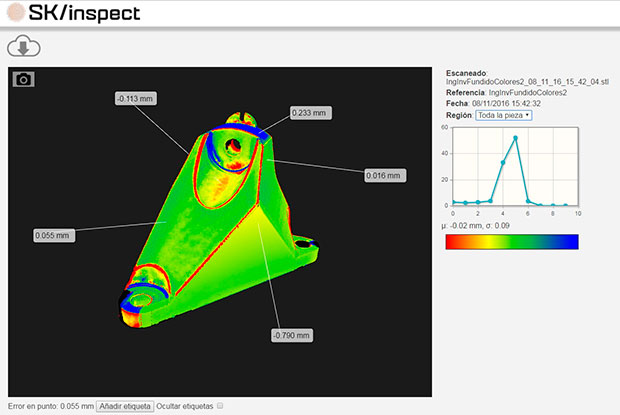

SK/Cell is a hardware and software solution for advanced inline inspection. It is based on the integration of a high-speed scanner in a multiple axle flexible robot. This contactless 3D inspection system works by structured light scanning technology. With the color mapping of the point cloud achieved by this technology, you quickly capture not only superficial datum, but also the elements’ ones, carrying out an analysis of the obtained images, for a precise measurement.

This robotized optical measurement solution would provide you with an efficient quality control in your manufacturing process, carrying out fast and precise measurements in a completely automated way directly in your production plant.

The robot allows you to automate the processes, at the same time the scanner with the structured light technique gets a point cloud which picks up all the information of the produced parts. Moreover, SK/Inspect software with which operates the solution, is designed to achieve inline measurements in an easy and intuitive way, as well as to communicate with your MES.

SK/Cell is a flexible control and measurement system to achieve high quality results, saving high quantity of time during the production and inspection processes. Scans, compares and gets reports automatically, with high usability for any production worker and with the opportunity to analyze the datum in real time, for the engineers and quality managers, no mind their ubication inside or outside de organization.

This product has been developed with the support of the INDUSTRY 4.0 program of the Provincial Council of Gipuzkoa

Related Products and Services

With this system you can use different softwares depending on your needs and uses. We will always advise you about the most appropriate complement for your company if you wish. Do not hesitate to ask us.

Applications

SK/Cell has been designed for inline inspection of automotive and aeronautic sectors´ parts.

This solution is suitable for measuring, processing and obtaining the more information possible in the fastest way, mainly for automated processes with high cadence of pieces. It is oriented toward inline measurements, integrating it in any production line offering an automated 3D measurement experience, from the planification and exploration, until the analysis and the reports.

Custom solution

Inspection time savings

With SK/cell solution, optimized for measurement in the production plant, you could save in time and costs, since it provides exact and necessary information not only for the designs, but also for the quality controls in a faster and more accurate way

Optimized for workshop measurement

You could move your quality control at high speed to the production space without the necessity of advanced training for all the production workers, this way you could simplify the measurement process, which results in a meaningful improvement of your productivity

Flexible solution

We offer you a flexible integral solution that adapts to all your needs

Customized solution

Our engineering department could personalize and adapt SK/cell to your requirements. Tell us which your challenge is and from Sariki we would advise you to identify which one is the best solution for your specific case