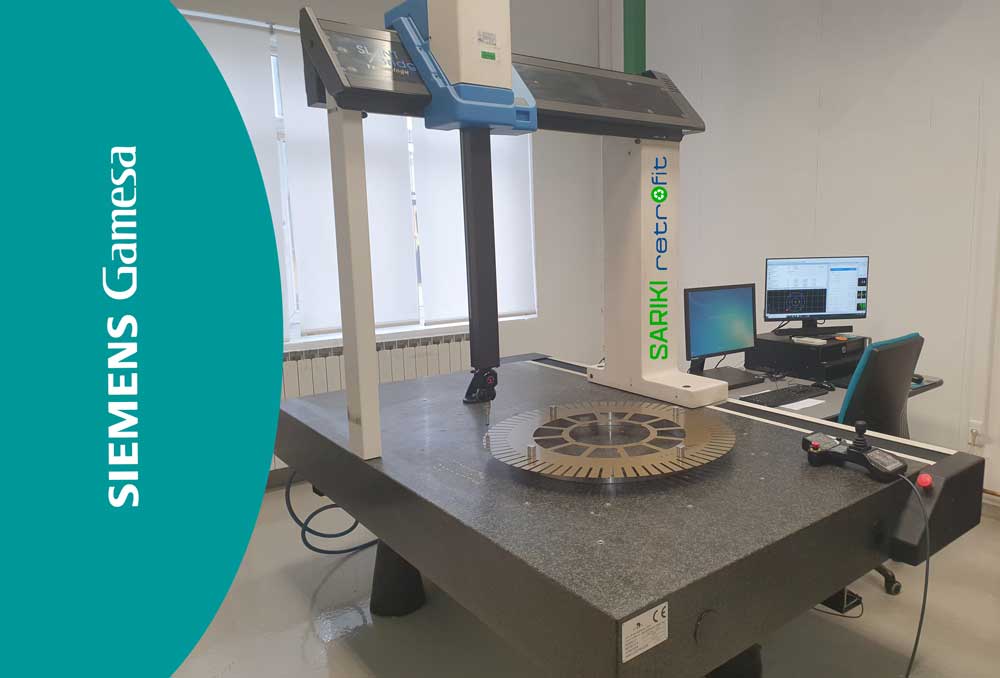

SIEMENS GAMESA updates its CMM and improves capabilities with the Mcosmos software

The Reinosa plant of Siemens Gamesa is specialized in the manufacture of large electric motors. In 1997 they acquired a bridge structure CMM, DEA MISTRAL 15.10.09 (X: 1500mm, Y: 1000mm, Z: 900mm) with which they have been performing dimensional inspections mainly of stator and rotor blades, as well as varied parts belonging to the electric motor.

In 2020, the capabilities of the machine did not meet the requirements of the company and contacted Sariki to look for alternatives and increase the useful life of the CMM.

Sariki proposed the electronic upgrade of the machine by incorporating a new Renishaw numerical control and two new softwares; Mcosmos and Measurlink.

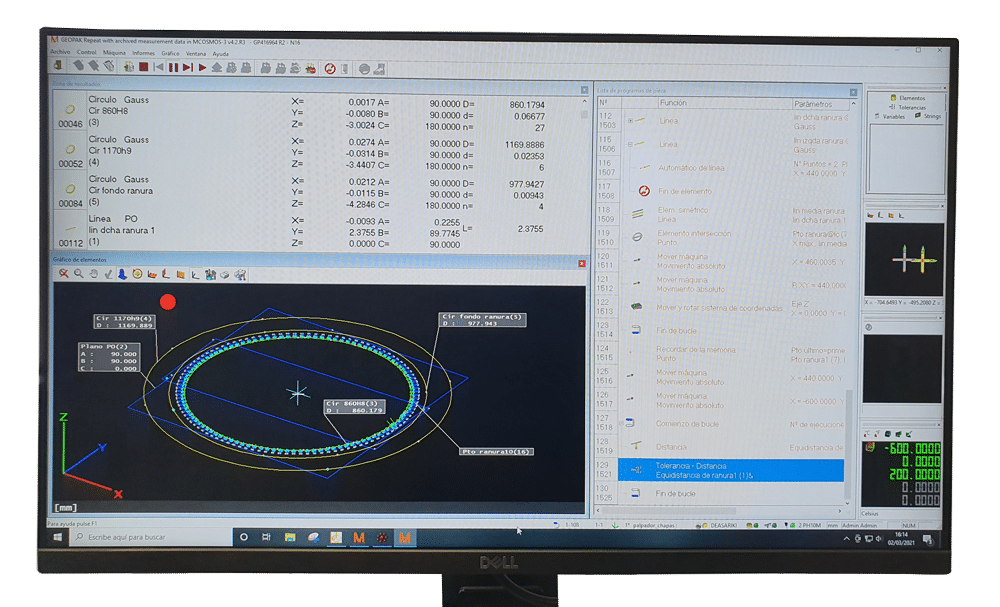

One of the main requirements that the DEA MISTRAL machine did not meet was the software

By implementing Mitutoyo Mcosmos software they have increased their programming capabilities, they are able to measure against CAD and machine users can program their parts more easily. In addition, Measurlink enables them to perform statistical process control today.

The Retrofit has allowed them to reuse all the accessories (probes ans stylus), as well as eliminate the problems of maintenance of old electronics. Failures in this generation of machines require a 1 week prior diagnosis, plus a shutdown of around 2-3 weeks of work and there is always the possibility that there are no spare parts.

Sariki's technical team has carried out on a scheduled basis the transfer of the machine to a new room, updated the electronics and installed the new software, performed the calibration and issued the ENAC certification through the calibration laboratory of the Unceta Group, Sarikal Calibración. In addition to the training of the software, they benefit from the support service to solve all the doubts regarding the software.

It has been a project adapted to the needs of Siemens Gamesa and has positively impacted both in terms of safety and greater capacity.

Follow the example of Siemens Gamesa: recover your machine, promote the circular economy and optimize your resources.

If you want to know more about the Retrofit service, follow the following link.

CMM upgrades and retrofit

Converting your old CMM to the new digital era and entering the world of the smart factory has never been easier.