How does industrial tomography work? 10 frequently asked questions about X-RAY CT.

In this article, we will try to solve the ten most frequently asked questions about 3D X-ray Computed Tomography. But first things first…

What is industrial tomography?

Industrial tomography, or industrial computed tomography (CT), is one of the most innovative technologies for identifying part’s internal defects. For this purpose, a non-destructive image capturing process is applied, using X-ray technology.

Traditionally, the only way to check parts internally was to perform destructive tests. But x-ray technology’s application to the industry makes it possible to visualize the part’s internal and external features in detail, saving destruction costs.

Many sectors have decided to opt for this technology: automotive, aeronautics, medical, etc., due to the advantages and possibilities that this kind of defect analysis allows.

Hereby 10 Frequently Asked Questions about X-ray CT, in order to understand the specifications of this new technology.

1. When is X-ray computed tomography used?

X-ray computed tomography is the best technology to obtain a fast, non-destructive, and detailed examination of different structures. Its application varies, from internal and external sides, industrial or even assemblies. With just a quick CT scan, structural and dimensional aspects of a part can be evaluated.

Summing up, it can be used in every phase of the product life cycle, whether to develop a new product to detect internal and external defects. Industrial computed tomography is the most versatile non-destructive technology for improving your product’s quality.

2. Where is industrial computed tomography mainly used?

X-ray CT is used in different sectors, such as the industrial sector or in academic research. In the industrial sector, it can be used for product development (R&D, engineering), in production, or in quality control, (failure analysis, etc.). On the other hand, in the academic sector, it is mainly used by research centers and universities.

3. How do I know that my part can be scanned?

In this case, part’s 2 main characteristics must be taken into consideration. The first one is the physical appearance. Smaller parts/samples and more localized areas of interest lead to a higher resolution result.

On the other hand, the composition of the part must also be considered. The density of the sample is crucial, because the X-ray power required to penetrate the material is not the same. For example, it will take more power to penetrate a gold ring than to penetrate a plastic bottle.

4. How long does it take to scan a part?

As with part features, scanning time can also vary. It can take anywhere from 2 minutes to several hours, depending on what you are looking for in the part, and the setup that the X-ray CT requires. It can take 30 minutes to detect a simple crack and see where exactly it is, or experience assembly issues due to different conditions and many hours to scan materials at high resolution.

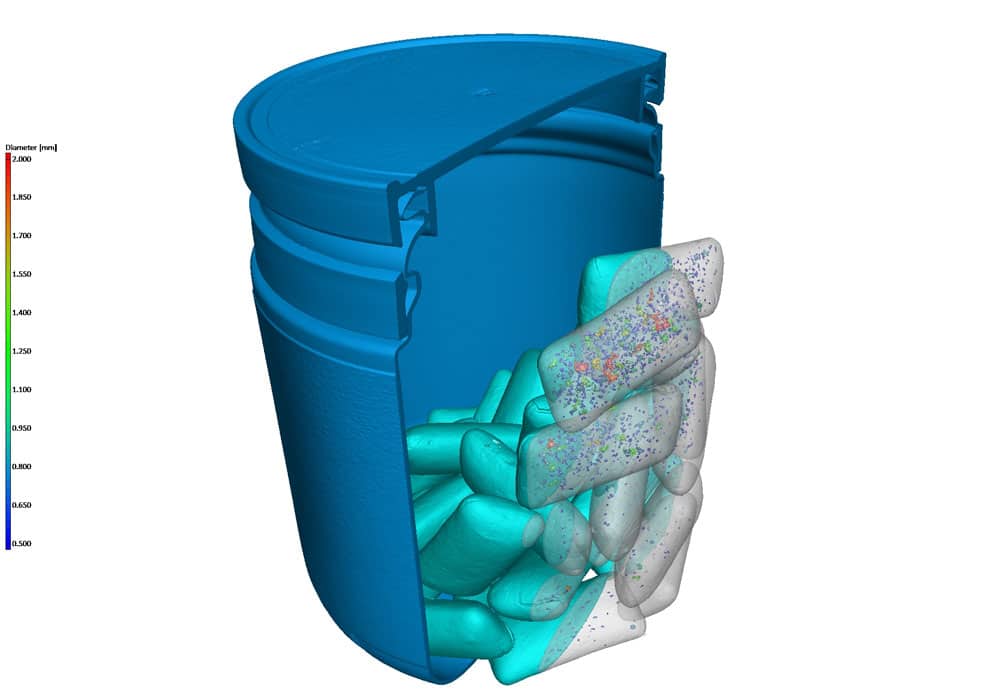

5. Can more than one part be scanned at once?

Multiple parts can be easily inspected in a single scan. Depending on the volume and density of the part, several parts can be scanned at the same time, which can be placed in the same sample holder. In the last step after scanning, the post-processing, the individual parts are automatically separated.

6. Can X-ray CT scans be automated?

With industrial tomography, automation is possible by adding a sample loader. X-ray CT systems equipped with such loaders can scan multiple parts without an operator’s intervention. For example, with the automatic overnight scanning mode, 24/7 operation is guaranteed.

7. How is a part scanned with X-ray technology?

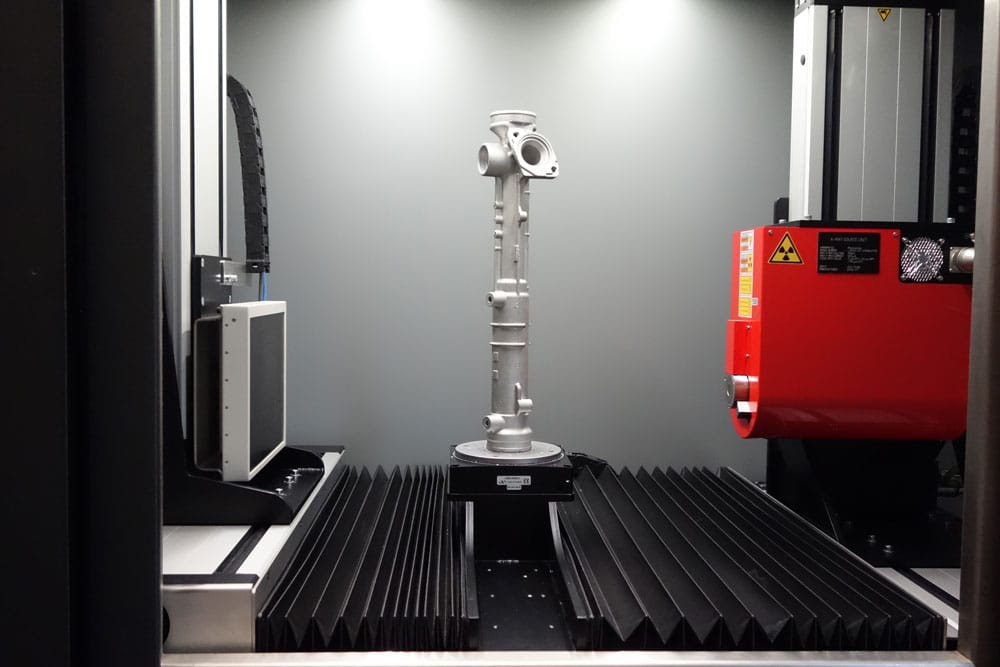

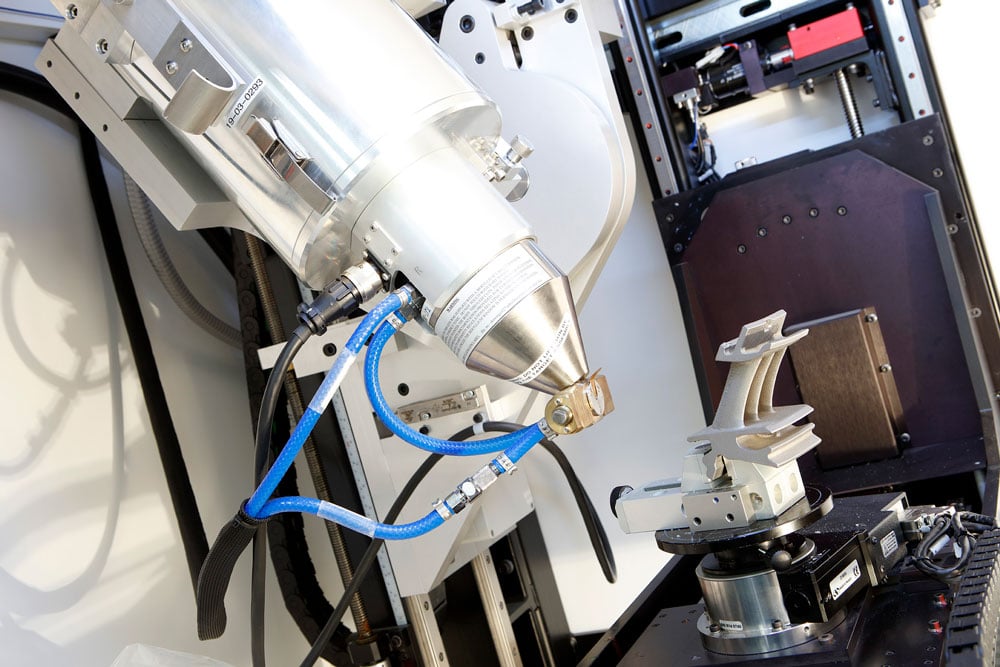

The working principle is quite simple and consists of two steps. The first one is the acquisition, where the part is exposed to the X-ray source and captures 2D X-ray images repeatedly in 360 degrees. The second step is reconstruction, where all the 2D images from the previous phase are reconstructed into a 3D rendering, allowing a thorough analysis of the part’s internal and external features.

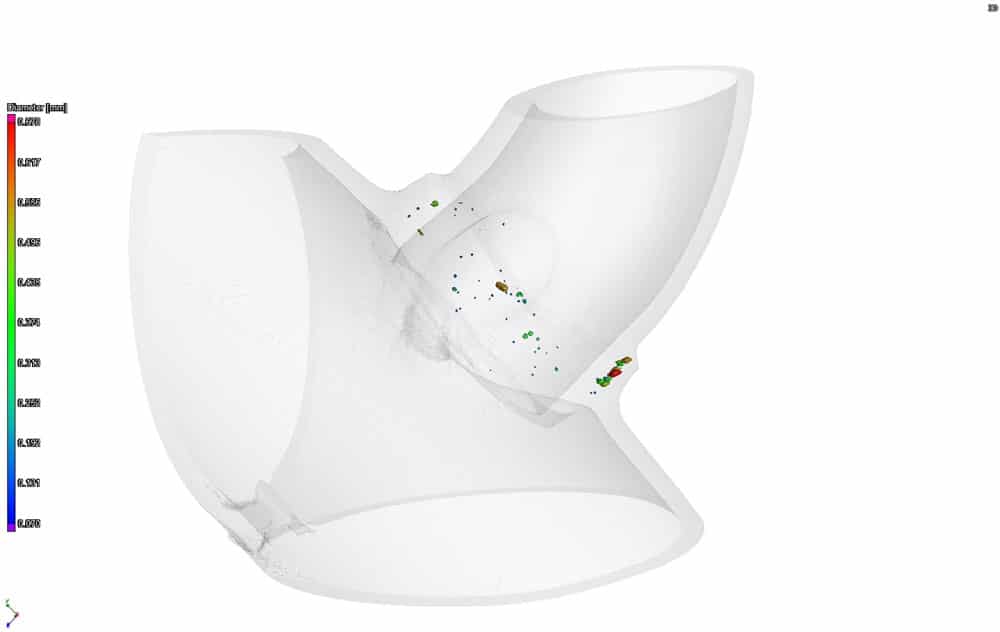

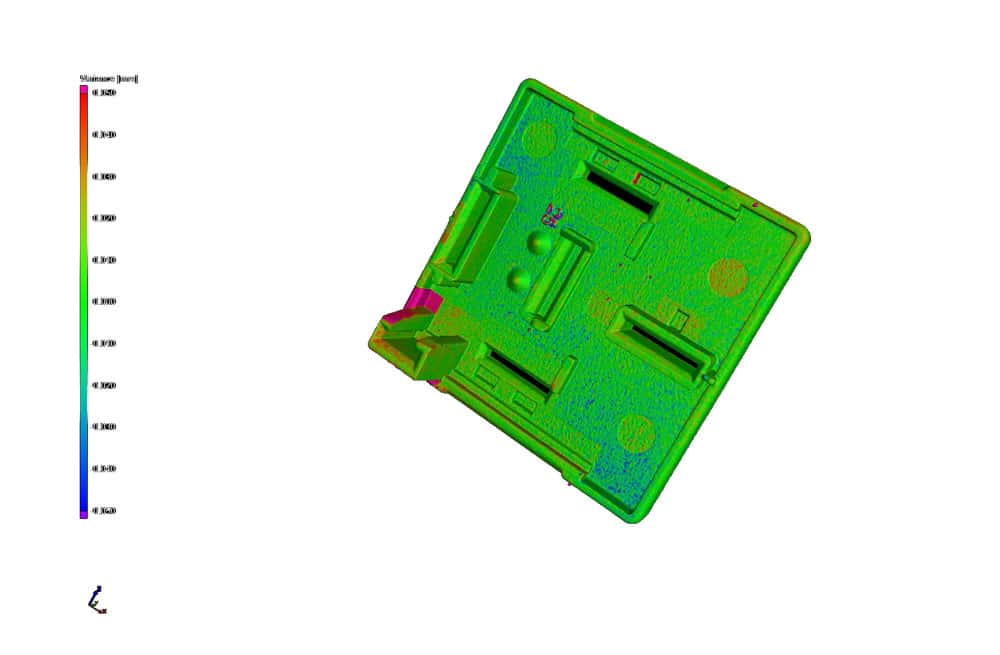

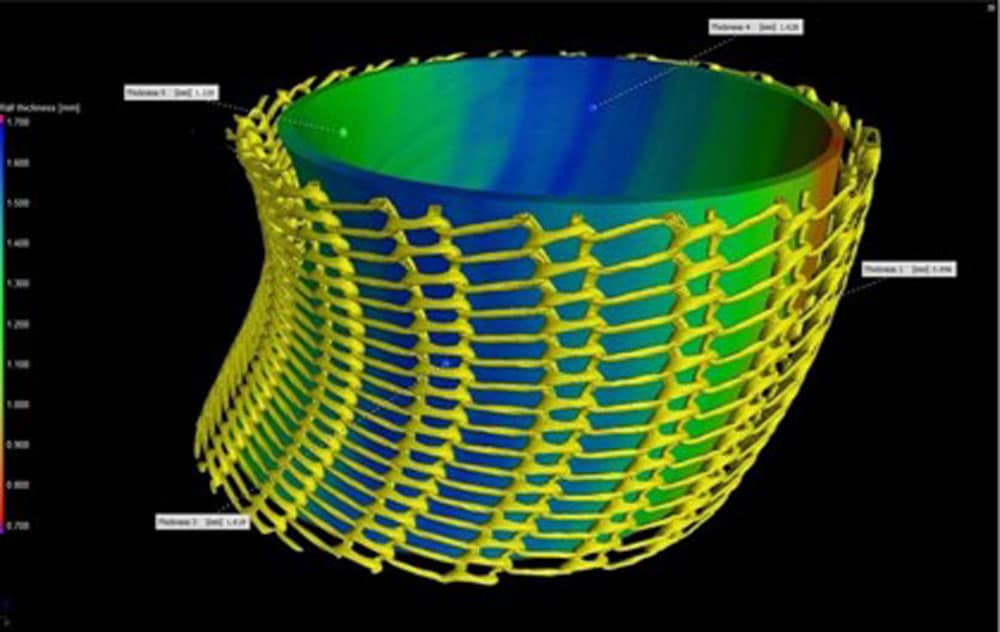

8. What can be seen in a reconstructed image?

In X-ray CT, the reconstruction is a process in which, after scanning the part, a powerful algorithm automatically generates a virtual 3D volume of the scanned part. This step takes a few seconds, and then you can work directly in the rendering, go through the sample, look for defects, check assemblies, locate cracks…

9. How can the quality of the reconstructed images be increased?

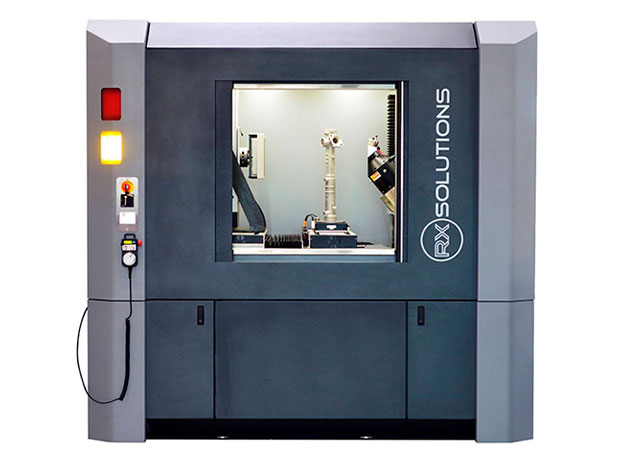

There are many parameters that affect the image’s quality, which is why RX Solutions simplifies their management with their X-Act tomography software. This software, which handles the whole process, offers an intuitive and ergonomic management of the following factors: averaging, number of images, calibrations, acquisition mode and artifact correction during reconstruction, among others.

10. Do you need to be an expert to use an X-ray CT system with your product?

It depends on the system and the supplier you are working with. RX Solutions’ computed tomography systems are designed to improve the user experience and make performance easy. That’s why little training is required to use this CT equipment.

Since the users may have different expectations and requirements, RX has adapted the ergonomics of their systems to facilitate its usage. To this aim, they have programmed a software with 3 different interfaces: “Expert Mode”, “Guided acquisition” and “Wizard mode”. This software streamlines the entire workflow, from CT setup to part reconstruction. Thanks to the X-Act software, only a few clicks are needed to start the scan, wherever the sample is.

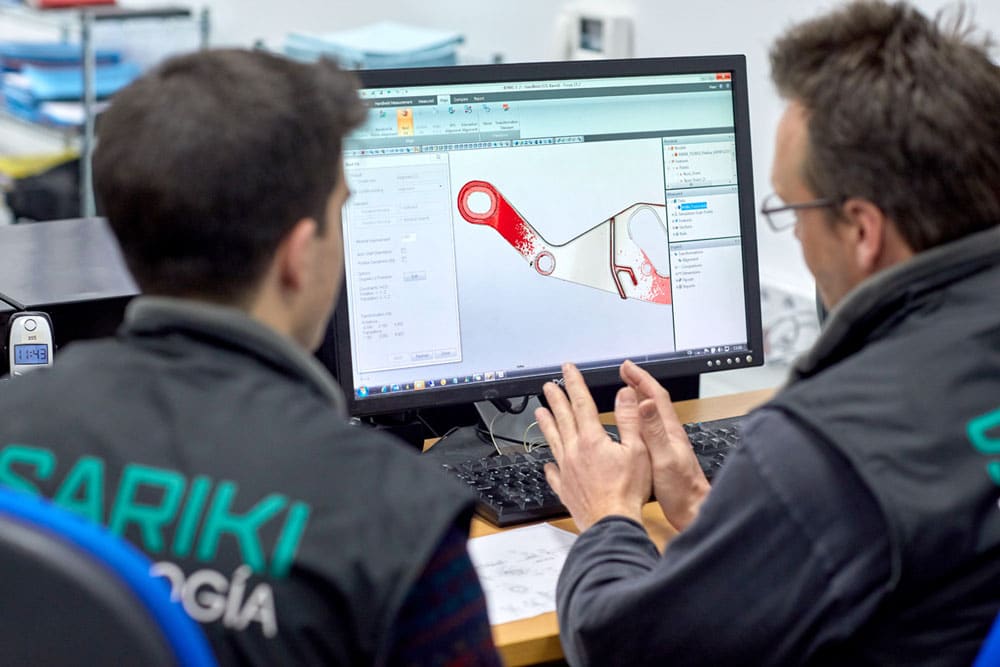

In Metrología Sariki we are committed to support you in your part verification process through non-destructive testing.

To this aim, we have both the measurement service with tomography, and the possibility of acquiring a customized solution from our supplier RX Solutions.

Do you have any other unanswered questions?

Contact us and we will answer all questions without any compromise.