The most versatile 3D laser scanner solutions on the market

Over the past 35 years, quality control, and especially dimensional inspection, has evolved alongside manufacturing technologies, responding to key needs of sectors with highly demanding and changing environments.

Metrology manufacturers have succeeded in developing non-contact measurement technologies that are already having a direct impact on improving product quality and optimizing processes.

At Sariki, we have always bet on collaboration with top-level manufacturers and experts and today we would like to present you the proposal that our supplier KREON offers to the market.

KREON is an expert in developing highly versatile non-contact measurement technologies.

It has a very complete range of laser scanners that can be integrated into a wide variety of equipment

Measuring arm

CMM

Robot

Machine Tool

A new range of high precision measuring arms has recently been released under the name ACE +.

The ACE + arm complies with the latest ISO 10360-12 standards, responding to increasingly stringent requirements in terms of accuracy and productivity. It works with the latest encoder technology and also features an advanced calibration method, ensuring exceptional levels of performance.

It has 5 models (from 2.5 to 4.5m) and can work with any of the following laser scanners (skyline, solano blue and Zephyr III range)

Zephyr III the most versatile laser scanner

The latest scanner on the market is characterized by its versatility. Not only does it allow its use in three-dimensional machines, it can also be integrated into robots and machine tools.

Zephyr III is a high precision (5 µm) and high resolution (15 µm) 3D laser scanner. Ideal for digitizing small geometries and with the option of joining a probe to combine both probes in the same measurement.

Turn your traditional CMM on a 3D scanning machine

It is very simple. It is enough to perform a RETROFIT to your current machine so that you can start using a 3D laser scanner together with your usual measurement probes and in this way carry out a complete inspection of the part simultaneously combining the contact measurement probes and no contact.

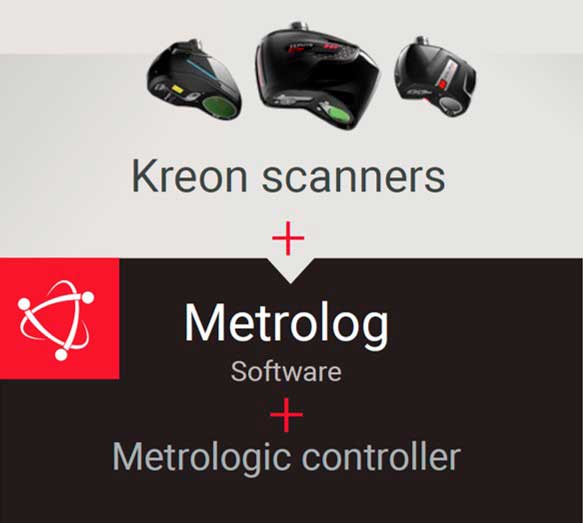

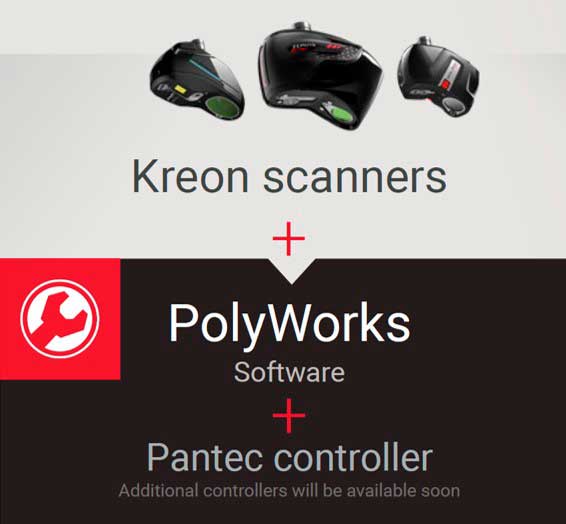

Kreon has different 3D scanner models to suit your needs and allows retrofitting with 2 turnkey configurations:

Full automatized integration

- A unique software to drive the CMM, the scanner and to process data.

- Possibility to automatically calibrate the scanner positions onto the indexing head.

- Use a probe directly connected under the scanner or switch between scanner and probes using an auto-change rack.

Renishaw compatibility

- PH-10 (T, M and MQ) power-operated heads.

- Auto-change racks (ACR3)

- IS1-2 switch

Robotized production inspection

Zephyr III can also be integrated into robots for fast and efficient non-contact quality control in the production process.

Kreon, Staubli and Metrolog have developed the CMR (Coordinate Measuring Robot) solution. It is a fully customizable solution that does not require targets or tracking systems to guarantee accuracy.

Kreon offers us the latest generation technology, high performance and versatility so that you can incorporate 3D digitizing technology in your company.

If you need more information on a specific product or want us to advise you, you can fill out the contact form or call 943848889