We present Vici Vision’s new range of optical measuring machines for turned parts

Vici Vision has just released its new range of optical measuring machines aimed at the dimensional inspection of turned parts and cylindrical elements.

This new range of solutions has been designed to improve production, reduce costs and increase efficiency even in small batches. It is composed of the Techno series, M series and X series.

The integration of these systems in the workshop makes it an exceptional solution for production control. Sariki has bet clearly for the development of measurement solutions in process, and Vici Vision technologies are ideal because they have an exclusive design for use in aggressive environments, has retractable sensors that are activated during loading and unloading (which can be manual or robotic), and has an integrated pattern and temperature sensors that allow direct use in production, and immunize the machine against thermal contrasts.

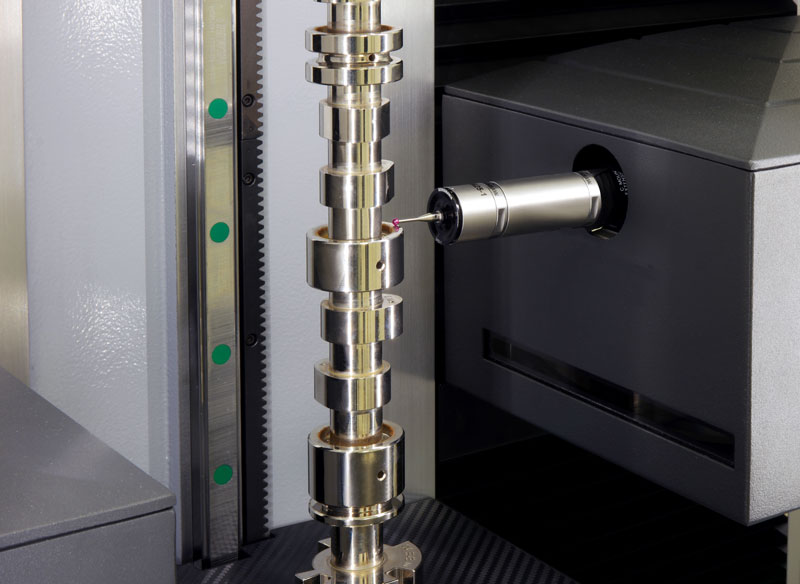

The techno series offers a completely new measurement function for the axes, combining the specific method of its optical technology and a contact probe measurement system. The manufacturer has added a 3-axis scanning probe from Renishaw, mounted on the top of the light source, which is interchangeable and covers the entire length area.

Nowadays, the combination of optical and tactile functions results in a complete measurement control for the machined parts in a single cycle. While the optical measurement system provides static, geometric and thread measurements, shape and nut measurements, the touch system detects features that are not optically visible.

If you are interested in a product demonstration, fill out the following form: