Metrología Sariki and Ekide Group ally to develop flexible in-line inspection solutions

We have initiated a strategic partnership with the aim of developing technologies for the high-speed in-line inspection field.

The manufacturing industry is undergoing a transformation directed to the implementation of Industry 4.0 concepts, such as process digitalization, in-line automation or the incorporation of the advanced manufacturing systems.

Large industrial production chains (automotive, aeronautics, railway industry, etc.), need to achieve the required quality levels in the produced parts, but they also have a set of needs that the main inspection system manufacturers do not cover in a holistic way: inspection of 100% of the parts manufactured at high cadence, adjusting to the cycle of production line, and requiring the processing of large information volumes.

In this context, Ekide Group, a technological solution developer based on artificial vision, and us, Metrología Sariki, engineering developer of in-process dimensional metrology solutions, have partnered to offer the market flexible solutions for in-process and high-speed accuracy inspections. The technology center Vicomtech, an expert in visualization technologies, collaborates in the alliance by contributing their know-how in vision technologies and information processing algorithms.

This partnership started in 2019, and several projects have already been developed for customers in the automotive sector.

“By developing technologically advanced products, the co-creation process has allowed us to achieve success in solving complex customer problems.”

Fernando Beasain

Business director at EKIDE GROUP

“The Alliance with Ekide represents a very important landmark for the development of Sariki’s own solutions. Collaborating with local companies is essential to continue growing as an organization. “

Borja Garate

General Manager of Metrología SARIKI – Unceta Group

“Being able to contribute our technological expertise to the industrial strategy, knowledge and product betting of our colleagues, is very satisfying for our organization.”

Gorka Marcos

Director of Technology Transfer at VICOMTECH

Solution’s added value:

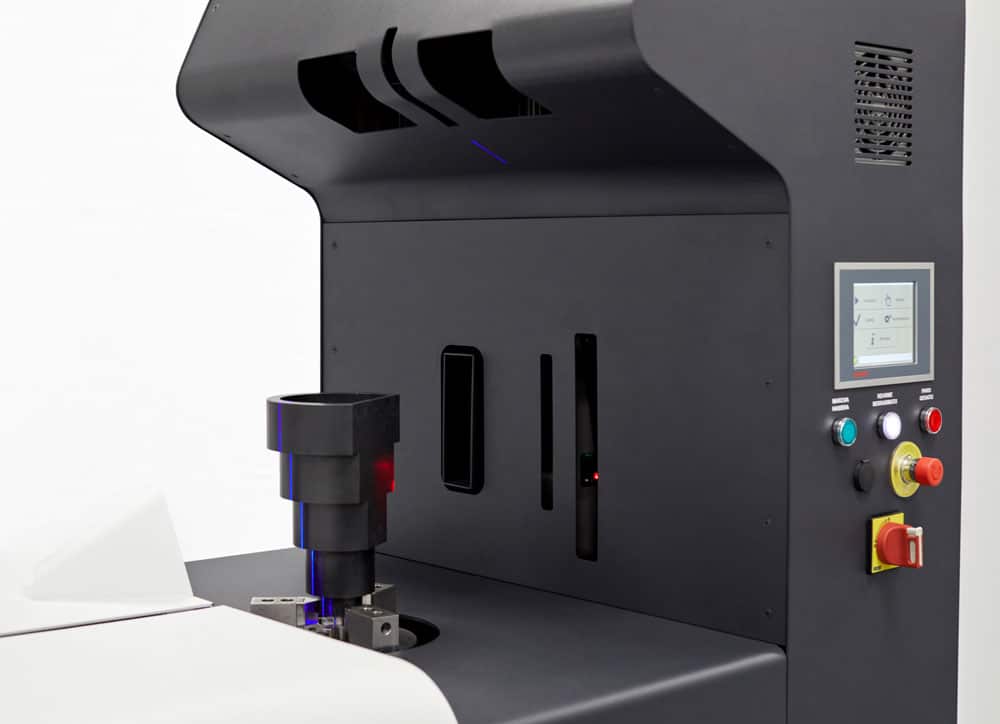

All the solutions are designed to ensure the inspection’s quality, working continuously in highly demanding production environments.

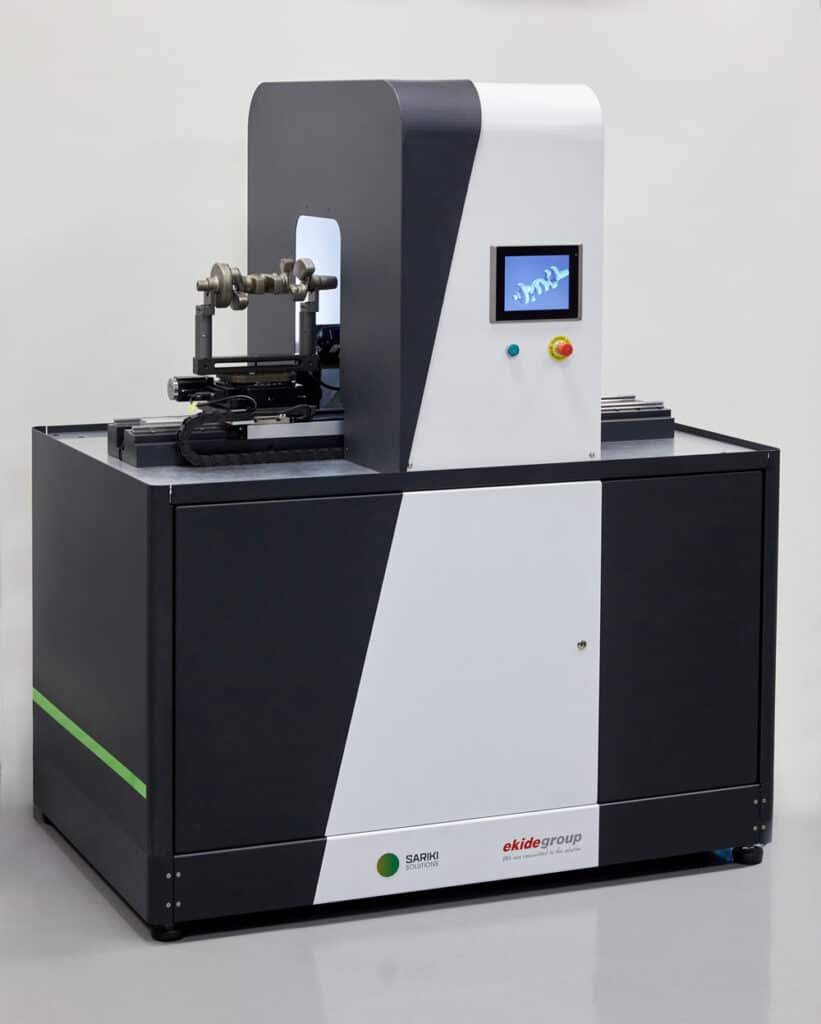

We currently offer 2 models (lineal and rotary) that are, at the same time, completely flexible:

- We select the high frequency scanners depending on the accuracy demanded by the application.

- The solution has an automatic adjustment system that allows to adapt the number and arrangement of the scanners depending on the geometry and dimensions of the parts to be inspected.

- We can cover all the industrial sector’s needs. They offer the possibility of developing and incorporating new functionalities to the application, in order to meet the specific application needs.

SK/inspect is the software used to perform the measurements and analyze the results.

It is a point cloud-based software, designed for the complete dimensional and geometrical evaluation of the parts.

It has a graphic interface designed to ease the interaction with the operator, and the data analysis is measured directly in-process. Moreover, the measurement data is exported directly to the web platform for the analysis from external stations outside the inspection cell.

3D model reconstruction

Part alignment

Calculation of element and cross-sections

Dimensional and geometric tolerances

Color mapping and deviation labels

Reports and databases

If your company is transforming and wants to optimize the quality control of its products, in-process inspection will allow you to optimize times and manufacture fewer defective parts.

Contact SARIKI and we will offer you advice without any compromise.