5 Reasons to Use 3D Scanning

3D scanning has revolutionized a variety of industries, from shoe design to supercar manufacturing. Structured light scanners work quickly and accurately. Sometimes called white or blue light scanners, structured light 3D scanners scan an object multiple times from every angle and turn a tangible product within seconds into a virtual design. Here are five reasons to use 3D scanning in manufacturing.

-

Saves Time in the Design Stage

Perhaps a product needs a new part designed based on preexisting objects. The need to reverse-engineer a new object aligns perfectly with the capabilities of the structured light 3D scanner. The scanner can get into every nook and cranny of the existing product and provide the precise dimensions of the space where a new part must fit.

3D scanners also save time when an alteration must be made to a current design. When the thickness of a ring or automotive part must be changed, 3D scanners work must faster than hand-drawn calculations.

-

Makes the Prototype Process Faster

Creating an accurate prototype often requires multiple attempts. Thanks to 3D structured light scanning, this process can be expedited. In fact, 3D scanning may reduce the number of prototype cycles necessary during the design and production process. A scanner not only measures cross-sections and identifies areas where an object is warped, but it also saves all data related to the scan. When the time comes to scan a new version of the prototype, comparing version data is fast and easy. When the time comes to scan a new version of the prototype, comparing version data is fast and easy.

-

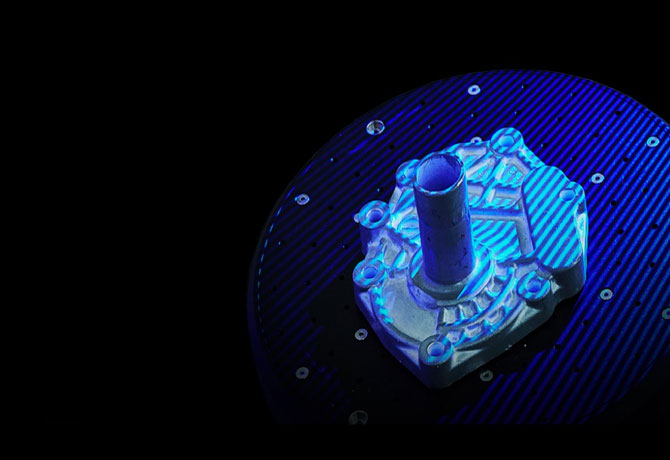

Fast and Comprehensive Quality Control

3D scanners are so accurate and helpful that major world museums are starting to rely on them to preserve some of the most famous artifacts from a variety of cultures. The scanner checks the composition of the material and the volume of the object. These same benefits translate to manufacturing uses. It’s possible to check the quality of design, scale and stability of a product within millimeters of accuracy. 3D scanning makes it possible to check the entire shape of the manufactured product with the original CAD design and find deviations instantly by displaying the data in a 3D whole deviation color map.

-

Ability to Remanufacture Parts Without CAD

When it’s necessary to remanufacture a part that originated before computer-aided design (CAD) software was available, 3D scanners make it possible to produce accurate reproductions. Simply scan an old part and use Reverse Engineering software to create a CAD model. The scanner can then be used to compare the newly created prototype to the scan of the old part to check for accuracy.

-

Easy to Compare Designs to Manufactured Products

Another advantage of structured light 3D scans is the ability to compare the as-designed model to the as-built model of a product. Ensuring that the original vision came to fruition as expected is an important metric of success. More than quality control, comparing designs to manufactured products ensures that the manufactured product will fit as needed, for example, in an automobile. Similarly, this cross-check could tell a jeweler whether a jewel will fit inside a pendant or ring.

Structured light 3D scanning is an efficient and precise means of manufacturing products that work as needed. Whether it’s an artistic restoration or engineering prototype, the projects used in 3D scanning require quality and accuracy, and structured light scanning delivers.

Ask more info filling the form: