High accuracy 3D measurement

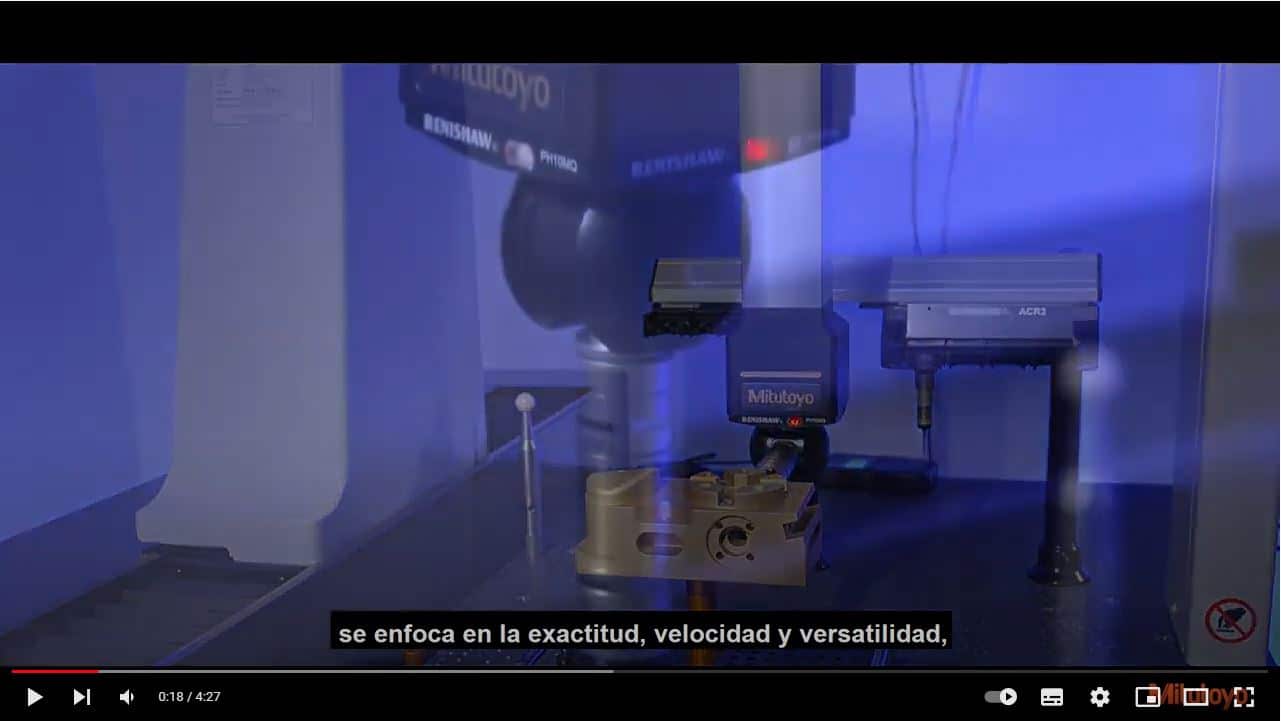

Crysta Apex V allows the assurance of the quality of your parts in a precise, flexible and at high speed.

Guarantees a maximum permissible error of

MPEE = (1.7 + 3 L/1000) µm [500/700/900 series]

Speed, accuracy and flexibility for your quality assurance

Ideal automatic 3D measurement solution: CRYSTA APEX V

Bridge type measuring machines are perfectly balanced systems that incorporate probes and software to guarantee optimal results according to your part requirements. It is a universal measurement technology whose investment is quickly amortized, since it allows to easily exchange both probes and software and thus adapt the machine to the requirements of the moment.

It allows you to verify the dimension of your parts accurately. Guarantees a maximum permissible measurement error of MPEE = (1.7 + 3L / 1000) μm [Series 500/700/900].

- The integrated thermal compensation system enables measurement at temperatures varying between 16 and 26°C by automatically calculating and presenting measurement results as if they were made at the standard reference temperature (20°C). This system works even when temperature gradients of 1 K per metre and per hour are experienced.

- Mitutoyo has developed the new SMS technology (Smart Measuring System), an intelligent measurement system that allows online monitoring of precision measuring instruments. You can view your machine information online as well as the accumulated records. 3 tools are available:

- Status Monitor (Smart Measuring System): Allows remote monitoring of the operational status of measuring instruments.

- Condition Monitor: Allows preventive maintenance through monitoring of current condition of coordinate measuring machine.

- MeasurLink: Reduces the production of defective parts through “Visualizing Quality.”

- CRYSTA-Apex V can be located both in the measurement room and in the production area. Due to the easy connectivity with conveyor belts and robotic loading systems, this machine is perfect for automated measurement applications.

It allows you to verify the dimension of your parts at high speed. Maximum driving speed 519 mm/s, Maximum driving acceleration 2309 mm/s² and Maximum measurement speed 8 mm/s.

It offers you flexibility. It can be equipped with almost any kind of probe, such as:

- Touch-trigger probes

- Scanning probes

- Laser scanners like Mitutoyo’s SurfaceMeasure

- Vision probe QVP

- Surface Roughness SURFTEST Probe

All probe configurations can be changed automatically within a measurement cycle. There are many kinds of probe changer available to meet the requirements of your application.

Related Products and Services

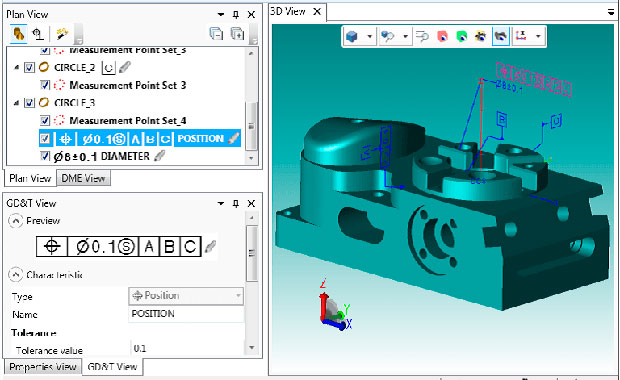

With this system you can use different softwares depending on your needs and uses. We will always advise you about the most appropriate complement for your company if you wish. Do not hesitate to ask us.

Related Products and Services

With this system you can use different softwares depending on your needs and uses. We will always advise you about the most appropriate complement for your company if you wish. Do not hesitate to ask us.

Applications

Crysta Apex V has been designed for high precision inspection of parts of the automotive, aeronautical, health, capital equipment, machine tool, consumer ... etc sectors. The equipment is suitable for inspection of machined parts, stamping, plastic / aluminum injection, turbine blades, gears, molds and dies ... etc.

From 405mm to 3.000mm

Measuring probes

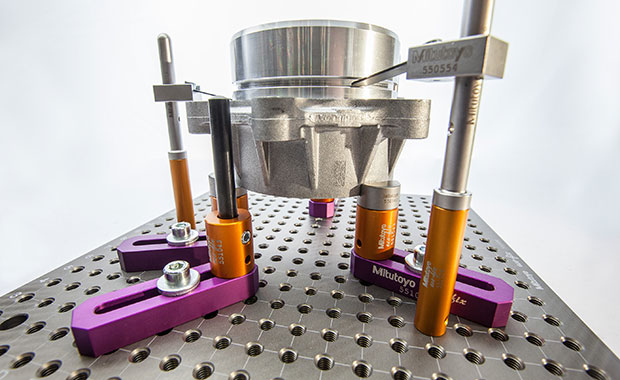

You will have a versatile and flexible system, which you can incorporate the following probes.

Tactile scanning probes such as SP25M or SP80 for fast measurement with high point density

High precision, touch-trigger probes with a tip size down to 0.3 mm for probing the smallest features

Vision systems for fast 2D measurement

Laser scanning probes for inspection and reverse engineering tasks

Surface roughness SURFTEST probe

Automatic changing racks to maximize machine efficiency

Custom solution

Our engineering department can customize and integrate the Crysta Apex V coordinate measuring machine according to your requirements. Tell us what your challenge is and Sariki will advise you to identify which is the best solution for your specific case.

LOADING SYSTEM

You can incorporate manual, semi-automatic and automatic loading systems into the equipment

CABIN SYSTEM

We identify the cabin system that best suits your application

INTERACTION WITH PRODUCTION MANAGEMENT SYSTEMS

We guarantee 100% traceability of the process by integrating the CMM data with your MES/ERP system

CUSTOM PROGRAMMING

We have experienced staff in programming and measurement for the realization and implementation of measurement part-programs

TURNKEY PROJECT

If you are looking for a turnkey project you can trust on us. We work with you from the conception of the idea and definition of project conditions, prior acceptance, installation in your company, user training and technical assistance and support throughout the life of the project.

We face integration projects from a holistic view of inspection guidelines and are committed to comply hybridization technologies. We can develop an inspection solution that combines different technologies: three-dimensional machine, roughness, vision, etc.

Technical specifications

Measuring range

X = from 500 to 900 mm

Y = from 400 to 2000 mm

Z = from 400 to 800 mm

Accuracy

(1.7 + 3L / 1000)µm

with SP25M probe

Repeatability

1,3µm

Driving speed

Up to 519mm/s

Driving acceleration

Up to 2.309 mm/s2

Temperature range

From 16ºC to 26ºC

Workpiece weight

From 180 to 5.000 kg