Increase your productivity by measuring alongside the CNC lathes with the new M1c optical machine

Discover the new solution that offers the fastest return on investment

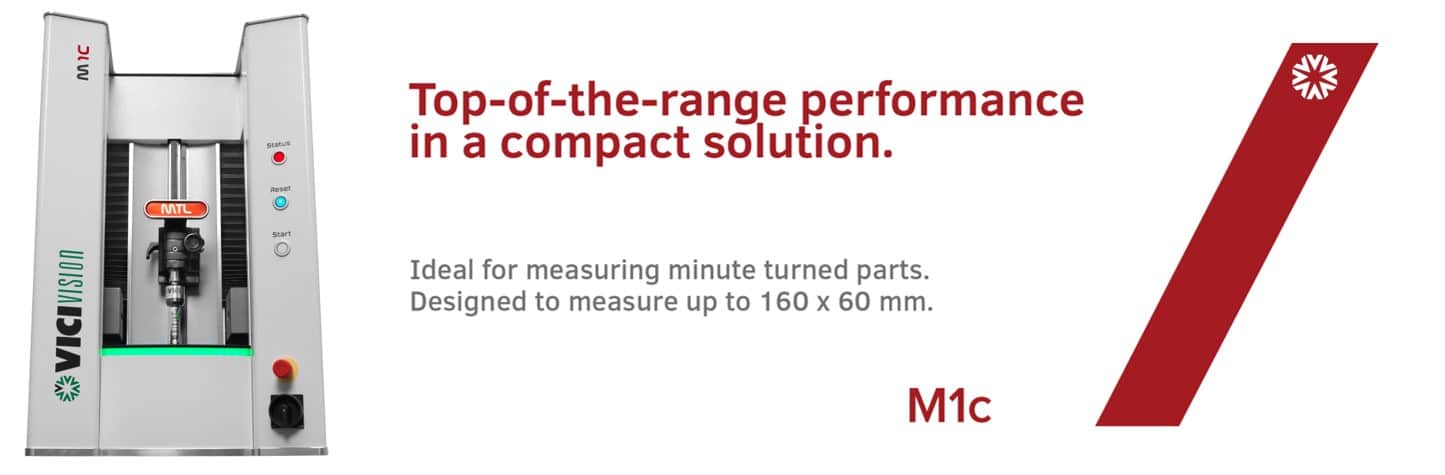

M1c is a fast and easy to use optical measuring machine, ideal for turned small metal parts, fittings or small-medium sized shafts.

It can be placed directly on the shopfloor next to the CNC lathe and used by the machine tool operator.

In a matter of seconds it can detect static, form and thread measurements, or compare a DXF theoretical profile with the real profile.

In traditional companies these operations are carried out manually by the operators, with micrometers, altimeters, profile projectors, spindle tips or even more complex instruments such as roundness testers.

In these cases dimensional inspection requires time as well as skilled or trained operators.

Measuring a part with traditional tools can often take from 20 to 40 minutes. It then takes time to collect results which are recorded manually with a high margin of error.

M1c produces the exact same results in less than a minute. All results are compiled in a measurement report and available in digital format.

This time reduction translates into major cost reduction that increases your company's competitive edge.

Increase productivity immediately

Substantially reduce scrap parts

Speed up batch change

If you need more information or want to be advised by one of our commercial technicians, you can fill out the form below.