Engineering & projects

Production metrology provides the sense and the point of reconciliation between quality and production within the workshop; It ceases to be a final sentence on a planned and completed productive activity and becomes a control medium that provides reliability and assurance to the processes, adjusting to the cycle times that production marks us.

Perform the control at the source preventing the error from being generated, with the objective of manufacturing “zero defects” or, in that process in which the error occurs, allows identifying the cause that causes it and being able to correct it before go to the next phase.

Your challenges are our challenges

- Guarantee production line cycle times

- Develop multi-reference turnkey projects

- With the minimum investment in fixtures

- With a unique probe configuration for all

references - Bulk parts delivery, automatic recognition for loading in measuring equipment

Technology and development

In line with the Lean manufacturing concept, at Sariki we offer you solutions for process control with direct and connected measuring equipment:

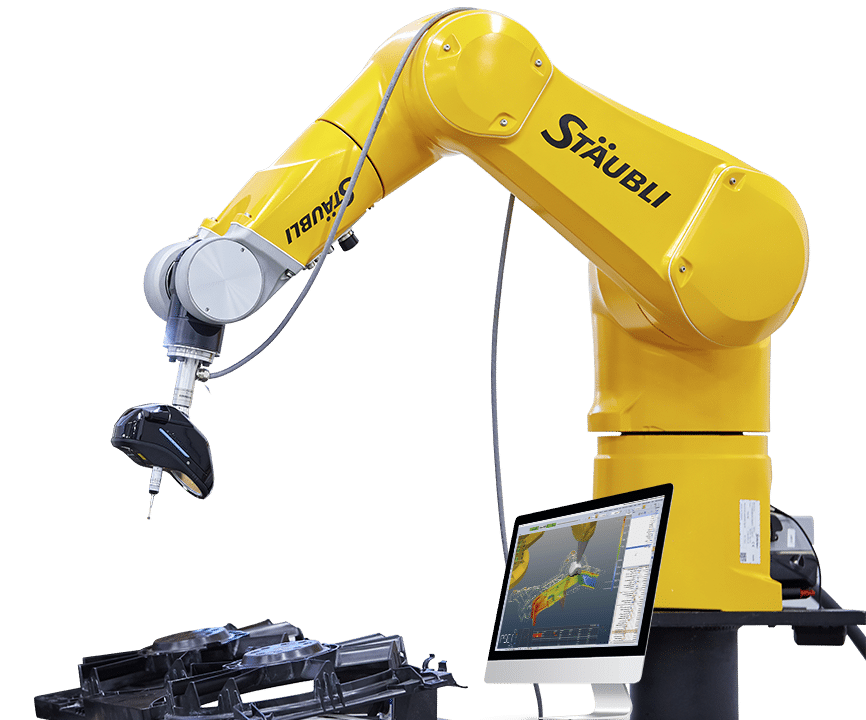

- Connected to the entrance and communicated with (robots, loading systems, cranes, safety barriers and equivalent)

- Connected to the rest of the plant (traceability of input data with ERP’s, MES production management programs,…)

- Connected to the output (traceability of output data to own SPC and export to customer-owned SPC, ERP, MES ...)

- We integrate into automatic lines with the possibility of including sensors and provide some intelligence (SmartFactory).

- We connect with robots and other automatic loading/unloading devices.

- We interact with production management systems, ERP, MES.

- We offer traceability data (barcodes, QR, for SPC treatment and analysis).

- Servitization, new relationships with the customer (remote control, augmented reality).

- Hybridization of inspection/measurement technologies, artificial vision.

Advantages

Our solutions are developed under flexible and universal, versatile measurement systems; programmable for the life cycle of a project and reprogrammable and adaptable for future projects.

The concept is based on the replacement of the current routine and manual tasks of the multicota control posts and control tools with this flexible equipment.

The operator has a real-time monitoring of the results with information on the variability of the characteristics measured (or dimensions) outside tolerance (for example, no presence of a hole due to a tool breakage, etc.). You can control the variability of the process, with which you can determine the behavior of the process or the batch of products and can carry out go-no go checks.

Experience and knowledge

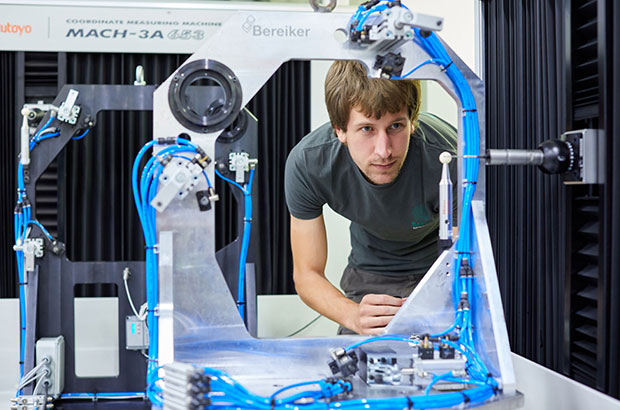

Experience has shown us that Mitutoyo’s specially designed machines for the workshop have better behavior in the specification level than the one described in their catalogs.

Structurally they are equipment with linear transmission systems, do not carry air skid, and are protected and fairing to withstand the production plant's own environmental conditions. They can also work at speeds and accelerations 3 times faster than conventional systems.

The Sariki project team is multidisciplinary and has been developing customized solutions for 15 years. We have measurement experts, electronics with integration capabilities, software developers ... who, depending on the challenge, work with engineering/integrators proposed by the customer or regular Sariki collaborators in order to offer the best solution.

How we work?

Analysis

We identify the challenge with the customer and perform a complete analysis of the requirements. We change risk for success to reach a real win to win.

Solution Design

Comprehensive study of the references to be measured that are within the scope of the project, plane and 3D CAD as well as a customer-defined measurement guideline taking into account the requirements of the plane. Acceptance of dimensions to be measured under the project by reference. 3D measurement simulation in machine volume, possible technology options, equipment models, specification of elements for point capture.

Definition of:

- Fixturing tool

- Traceability and connectivity (input, output); connected and smart factory

- Layout

- Custom display interface

- Result treatment

- Type of study for machine acceptance (R&R)

Implementation

- Pre-acceptance of the solution proposed by Sariki (repeatability of the measuring system/fixture with manual loading)

- Implementation phase and pre-acceptance (in integrator premises), repeatability of the system with automatic loading.

- Implementation in customer premises and acceptance.

- Operational training system.

- Delivery of specific user manual.

- Customer support at the start of production.

Service

- Specific contract conditions for inline equipment. Service level tailored to the needs. Predictive maintenance, definition of preventive guidelines for the operator (daily, weekly, monthly) as well as semiannual and annual maintenance by Sariki team.

- Remote assistance in case of incidents, changes in programming, Smart services.

Case study

The GKN Driveline Legazpi project has focused on the problem of measuring high precision automotive components along cold forming forgings. The project was developed during 2014.