GKN Driveline Legazpia

The GKN Driveline Legazpi project has focused on the problem of measuring high precision automotive components along cold forming forgings. The project was developed during 2014.

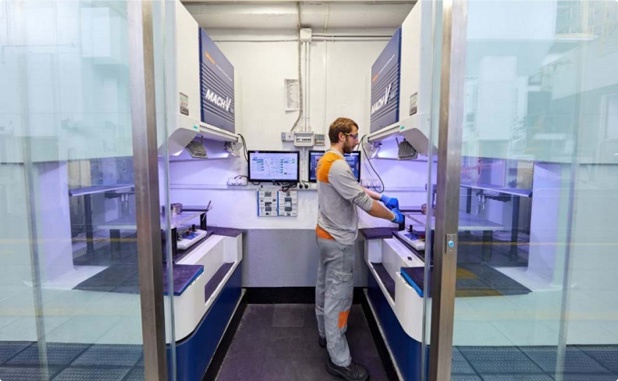

Tecnology: Mach V

Sector: Automotive

GKN Driveline Legazpi has opted for Sariki to face a very ambitious project of inspection in production, where the environment has undoubtedly been one of the elements that have made it a real technological challenge.

The firm of Legazpia specialized in the production of high precision forgings for automotive propulsion systems, needed to perform a high precision control of its cold forming line (tulips and outer races).

Sariki proposed to install two special measuring machines for the production environment. It is Mitutoyo’s MACH-V model, specially designed to measure at high speed, with a compact design to favor its installation in the plant and with temperature compensation.

Two machines MACH V 565 have been installed, on a floating floor for high vibration environments, at the foot of the forge. The application department of Sariki has developed a user interface aimed at staff with no knowledge of metrology, with references associated with its CAPTOR database, in order to guarantee the total traceability of the process.

The inspection is carried out by the operators of the stamping line. A randomized unit control is performed every half hour, both point-to-point and continuous. In this way, the press operator has real-time information on the state of production.

From the beginning the positive impact of the solution led to a total bet by GKN Driveline Legazpi. This strategic cooperation addresses the proposed challenges and has enabled the opening of even more ambitious projects for the future, demonstrating the achievements that can be obtained when working in cooperation between several companies.