Big parts

Easy Tom XL, is a highly flexible X-ray CT system up to 600mm x 720mm inspection volume.

Seven linear motorized axes enabling optimized magnification for various sample types and scanning configuration. EasyTom XL is available in different configurations: Micro-focus, Nano-focus or Dual Tube.

High resolution 3D Computed Tomography

Real time high resolution 2D digital radioscopy

Mobile detector

Hamamatsu monobloc source. Less maintenance because it does not need a cable connection

Micro or nano and combined versions available. To change the source in the combined tube configuration, it is enough to modify the variable in the software, it does not require physical change

The panel and the source move vertically to capture the total volume of the part, and the panel can be approached also to the part. It is a differential aspect that allows you to save time in the scanning process and reduce the voltage

X ray tubes: 150Kv, 150Kv-160Kv, 160Kv, 160Kv-199Kv and 230-199Kv

Voxel resolution down to 350 nm/voxel

Large inspection volume (diameter x height: 320mm x 720mm)

Possible in situ μCT

Programmable automatic control cycles

Great versatility for a wide variety of applications and analyzable products

Lead/Steel construction and X-ray safety interlocks, designed to meet X-ray safety regulations

Open and comprehensive system, with programmable automatic control cycles

X-act Software

- Large variety of acquisition modes: conventional, helical, laminography, shift and stack modes

- Programmable automatic calibration and stabilisation

- Remote control, scripting and serial communication

- Easy and intuitive 3D optimization of the sample reconstruction volume

- Semi-automated wizard enabling non expert users to get satisfying results

- Powerful and easy to use reconstruction artefacts correction algorithms

- Open tube interactive autofocus

Applications

Computed tomography is a powerful technology that allows you to inspect components in an easy way. The only one that offers you the possibility of seeing the interior without having to cut or destroy your sample. The only limitation is found in the density of the parts.

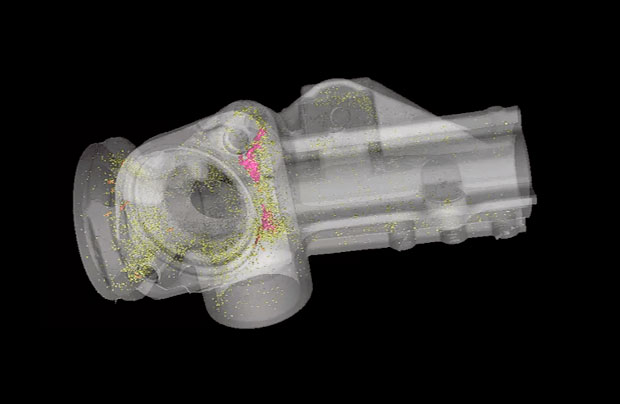

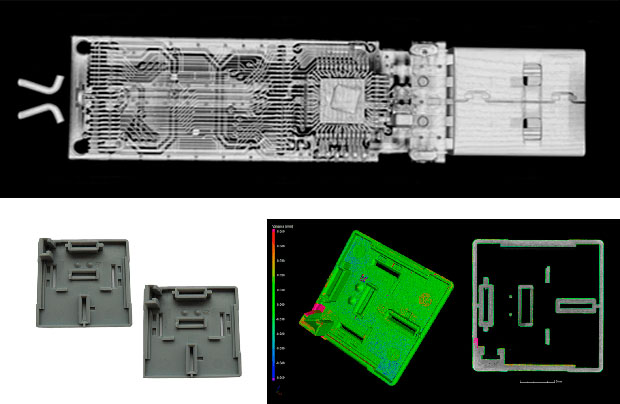

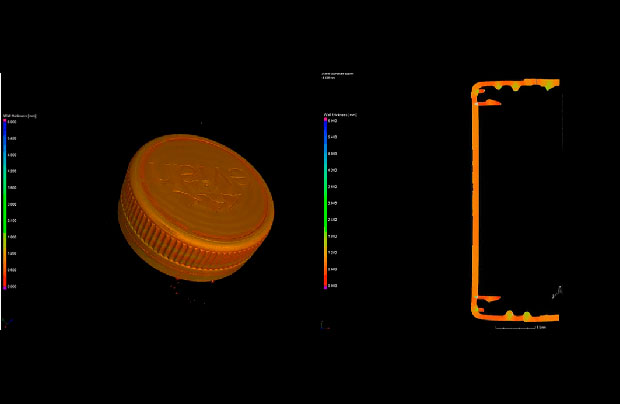

Many types of applications can be made using CT, from typical industrial problems such as the detection of defects in your samples (gaps, cracks, porosity analysis) to metrology on external and internal surfaces of complex samples. Diverse sectors: automotive, aeronautical, plastic, electronics (assemblies), academic, research and medical.

Custom solution

We accompany you throughout the life of the project: definition of the project, installation, training, programming, user support, software updates, technical assistance, calibration and maintenance.

Technical specifications

Micro

Resolution:

4 µm

Maximum scanned volume:

600mm x 720mm

Maximum sample weight:

100kg

Nano

Resolution:

0.4 μm

Maximum scanned volume:

220mm x 350mm

Maximum sample weight:

20kg

Ultra

Resolution:

0.4 μm

Maximum scanned volume:

520mm x 650mm

Maximum sample weight:

80kg