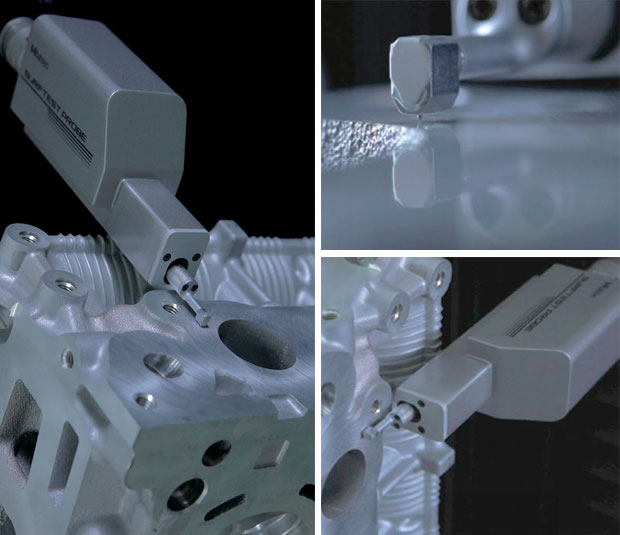

3D measurement with roughness tester

The surface roughness technology can now be used directly in the CMM. Instead of having to take the workpiece to another measuring device or use additional portable systems, the SURFTEST probe adds the roughness measurement capability to your 3D machine and, thus, avoids all the cost and inconvenience of additional systems.

Ideal 3D measurement solution with integrated roughness tester: SURFTEST PROBE

SURFTEST probe brings the proven technology of the SJ-310 series to the CMM with all its highly capable range of detectors developed for handling specialist applications such as roughness measurement on gears, inside small holes or deep grooves, in addition to simple flat surface measuring tasks.

Benefits

Choose from five types of detector for variant applications

High accuracy – no CMM movement during measurement

One CNC measurement cycle produces all results

Graphical and numerical output

One Measurement report for all GD&T requirements

Applications

The SURFTEST probe can measure roughness and waving of a large variety of machined and cast parts, bearings, shafts, seals, bearings, rollers ... etc.

Technical specifications

Length to drive

17.5 mm (the free running distance before and behind measurement is also included)

Driving method (*)

One reciprocating movement

Tracing speed (**)

Measurement:

0.25 mm/sec

0.5 mm/sec

0.75 mm/sec

Mass

350 gr

Range/Resolution

AUTO / Dependent on a measuring range

360µm / 0.006 µm

100µm / 0.002 µm

25µm / 0.0004 µm

Probe mount

Renishaw Autojoint