Umbor

Maximum accuracy level in 3D touch and laser scanning with Mitutoyo.

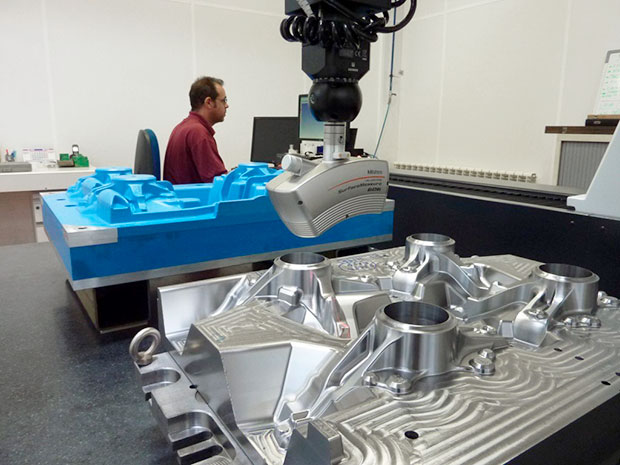

Tecnology: Mitutoyo Crysta Apex S

Sector: Automotive

Umbor is a company located in Vitoria which was founded in 2003 and specialized in the manufacture and recovery of cast tooling for customers, mainly from the automotive and aeronautical sectors. Umbor innovates in the manufacture of cast tooling with the state-of-the-art means existing in the market.

Umbor fully committed to offering the best product with the maximum level of quality and accuracy, has focused itself on the free-form laser scanning technology on tridimensional measuring machine and has found in Mitutoyo – Sariki the ideal partner to ensure the maximum accuracy level.

Umbor, specifically, has acquired a 3D measuring machine Crysta Apex S 12.20.10 of Mitutoyo equipped with the laser scanner solution SurfaceMeasure and continuous scanning probe SP-25 of Renishaw to scan quickly and efficiently 100% volume of the mould with an uncertainty lower than 0.01 mm. The application of these new technologies provides Umbor with the advantage of being capable of carrying out much more accurate and comprehensive inspections of free surfaces that the traditional inspection point by point, as well as in a much shorter time.

The SurfaceMeasure scanner of Mitutoyo scans surfaces of 60 x 60 mm. with a resolution of 0.06 mm. and incorporates a unique technology of automatic adjustment of sensitivity allowing it to scan bright surfaces (and even changes in colour) without the need of applying any type of spray. The result is a high quality point cloud ideal to carry out measurements and inspections by means of part-to-CAD or other point cloud comparison. In addition, it enables to collect the best information so as to be able to deal with reverse engineering tasks.