Satuercas Group

Satuercas group committed to automate production control in collaboration with Sariki and Mitutoyo.

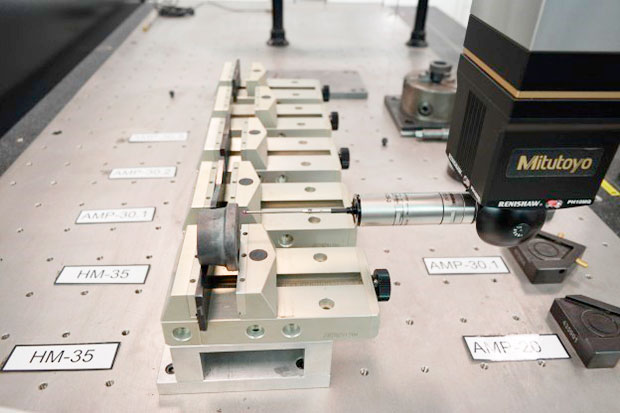

Tecnology: Mitutoyo Crysta Apex S

Sector: Automotive

Satuercas group located in Vizcaya, is committed to automate the production control and has started a project that will allow them to improve their quality control process throughout the business group.

Satuercas and Sariki-Mitutoyo have collaborated since 1991 and during the last years our customer has taken key steps to transform their production control system.

In 2016, they decided to invest in a three-dimensional measuring machine Mitutoyo Crysta Apex S 7106, with a greater working volume and new capabilities to perform continuous measurements. At this moment they are able to measure form errors, flatness, perpendicularities (they can measure more dimensions than before) and thus have more information.

The results obtained from measurements are collected automatically and the operator has no influence on the measurement. This allows them to offer greater security to their customers.

Management have decided to go a step further and they have now started the first phase of a very ambitious project that will transform their control system. The objective is to serve the 7 production machines located in the workshop with the Crysta Apex S 7106 three-dimensional machine.

The machine is located in the quality room and through a button system which emulates machine door opening, closing and shutdown, plant operators following the defined control plan, measure in three shifts when changing tools and every hour.

The three-dimensional machine has all the measurement programs of the different references that they manufacture and when the operator is there, the program indicates on the screen which is the reference that is currently being manufactured on his machine. The operator types his operator number, fixtures the piece and starts the measurement returning to his job. The process is fully traceable, data is exported for statistical tasks and the results report is stored on the server. The operator can visualize the report from the computer of his machine in the workshop and make decisions in case there is any out of tolerance.

The second phase involves the relocation of the three-dimensional machine next to production area, once the entire process has been validated. In a third phase, they want the three-dimensional machine and production centers stay nurtured and correct the manufacturing process in real time, impacting on the improvement of the productivity of the plant.

About Satuercas

S.A. de Tuercas is a corporate group that makes components for the automotive sector (Estamcal, Mecanifran and Actiro). https://www.satuerca.com/