Mapvision Q

100% in process measurement

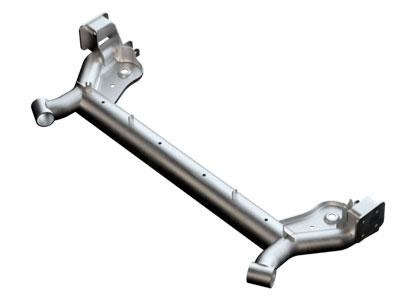

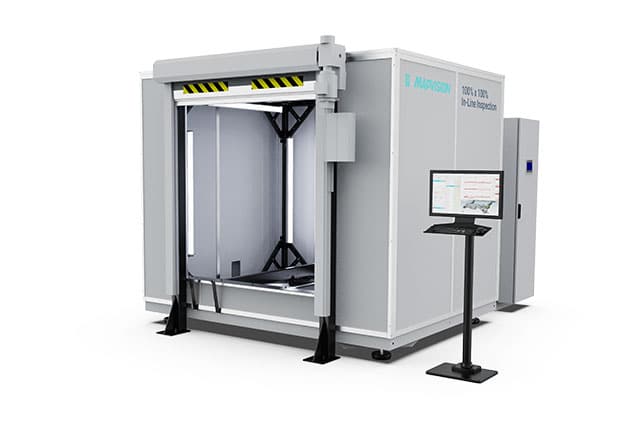

Mapvision Q is a 100% in process inspection system for compact chassis, body and transmission components such as trailing arms, side beams and axle components.

Mapvision technology is the world’s first self-diagnosing, fully-digital multi-camera inspection technology. Photogrammetry, vision and CAD are the basis of this solution that allows you to measure each characteristics of each part within the cycle time of the line.

Ideal solution for 100% in process inspection: Mapvision Q

Mapvision Q helps you not to send bad parts to your customer. Identify if you are out of dimensional tolerance, detect defects (presence of bolts, nuts and threads) and lack of components. You will get the most benefit if you place it behind the welding line.

It also helps you adjust your process. Get your pieces closer to the nominal and adjust the process in real time. Mapvision provides 100% traceability by storing all information and giving the possibility of re-inspecting all parts. This means that you will be able to control even the pieces that are on the road.

Accepts all part sizes, regardless of complexity

Applications

Learn about our specific solutions for: cross car beams, subframes and twist beam axles.

Custom Solution

We offer an integral solution suited to your needs. Experience tells us that collaboration with the customer is the basis of the success of this type of project and therefore from the beginning we work together to identify what are the main requirements and propose the best solution

In all projects we include the MapCare service. Includes support, calibration, annual maintenance and software update

We accompany you throughout the life of the project: definition of the project, installation, training, programming, user support and technical assistance. Sariki is formed by a team of 60 highly specialized people with more than 35 years of experience in the field of metrology

You also have the Green part program service available. We adjust the process with you and offer you advice and training