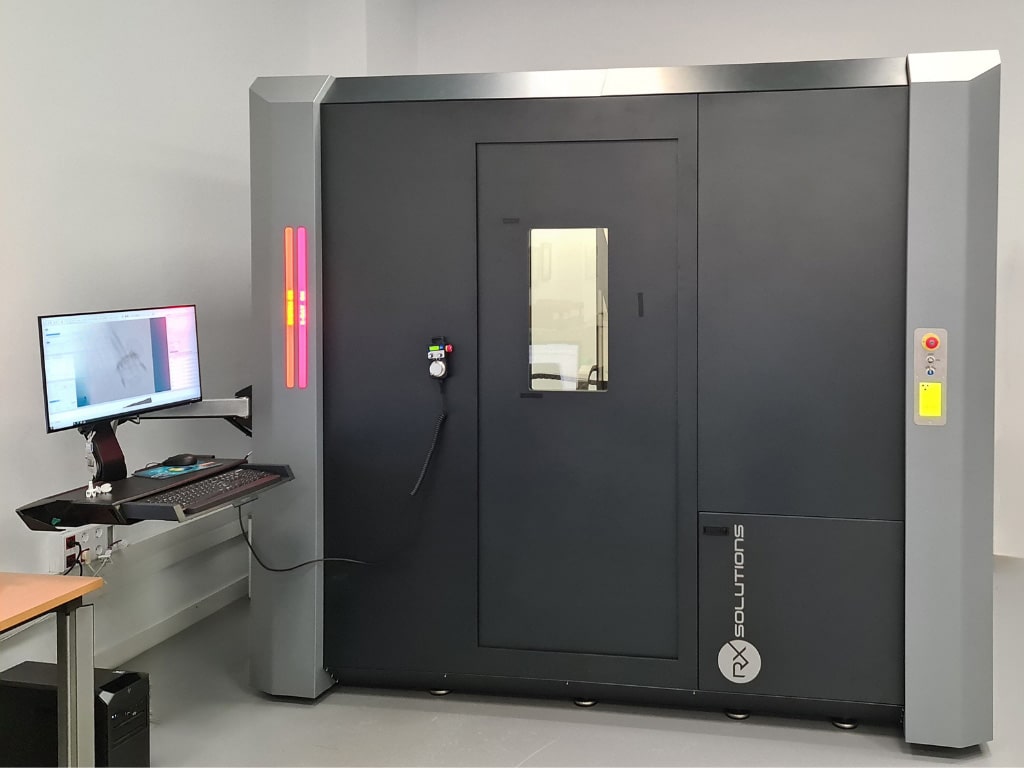

Non-destructive tests with micro-tomography

Computed Tomography

The tomography measuring service will allow you to identify defects and verify the geometry of your parts internally and externally using X-ray technology

This technology is suitable when you cannot perform destructive tests and need to verify your parts with high precision.

We have 2 equipment to be able to cover diameters of up to 600 mm x 720 mm and microfocus resolution of 4 µm.

- EASYTOM XL 230-199kV

- XT H 225-199 kV

We can perform:

- Acquisition of point clouds both of internal and external parts (visible and hidden)

- STL and CT generation

- Dimensional analysis (GD&T)

- Structural analysis

- 2D porosity (p201-p202)

- 3D porosity (volumetric porosity)

- Reverse engineering

- X-ray

- Analysis of internal structures (assembly of parts)

Using advanced analysis software, the presence of pores or internal defects can be detected, as well as the measurement of inaccessible internal dimensional characteristics.

Likewise, it is possible to analyze the behavior and adjustment of assemblies, inspection of complex components of injected plastic, analysis and test of materials.

If you need advice, call us without obligation at 943848889 or fill out the contact form.

In the following videos we will tell you the keys to industrial tomography technology and we will present you some customer work.