3D measurement

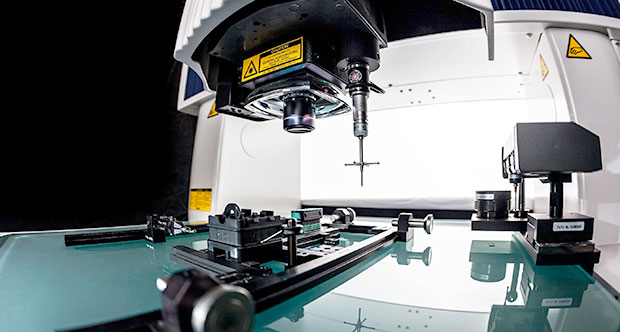

Quick Vision, is Mitutoyo's top range in image processing technology.

It has the latest technology to adapt to the most demanding requirements. You can turn your machine into a multi-sensor device by adding the contact probe option. Through a system of autochanger you can combine measurements without contact and contact.

You can choose between 6 machine models:

Quick Vision Active (2,0 μm)

- New CNC Vision measurement system

- Interchangeable objectives: 1X, 1.5X and 2X

- Available in two sizes: 200 and 400 mm

- High-accuracy fixed-bridge design

- USB high-resolution color camera

- Newly designed zoom system with interchangeable optics

- Vision and touch probe available

- Field retrofittable

- 3D measurement system and software

- 0,1 μm resolution glass scales

QV Apex Pro (1,5 μm)

- CNC Vision measurement system

- Available in three sizes 300, 400 and 600 mm, all achieving 1,5 μm accuracy

- Fixed-bridge design for maximum repeatability, acceleration, stiffness and accuracy

- Programmable ring light with parabolic mirror design and modifiable angle of incidence to maximize work-piece illumination

- Includes pattern focus optical enhancement hardware to measure translucent and reflective parts

QV ACCEL (1,5 μm)

- Large-format CNC Vision Measuring System

- Moving bridge design uses high-speed acceleration with high throughput to meet production inspection needs

- Large-format stage

- High-resolution camera

- Vision and touch available

- Field retrofittable

- Available in sizes from 800 to 2.000 mm

- 0,1 μm resolution glass scales

- Includes pattern focus optical enhancement hardware to measure translucent and reflective parts

QV STREAM PLUS (1,5 μm)

- CNC Non-stop Vision Measuring System

- Up to 12x faster than conventional systems using strobe-pulse illumination with image capture technique (20 mm/sec)

- Add TAF (Tracking Auto Focus) to provide automatic part Z-axis workpiece focusing

- Automatic and asynchronous image processing

- Examples: electronic packaging, metal stamping and plastics

- Includes pattern focus optical enhancement hardware to measure translucent and reflective parts

QV Hyper Pro (0,8 μm)

- High-accuracy CNC Vision Measuring System

- Sub-micron (0,8 μm) accuracy vision measurement system

- High-resolution 0,02 μm scale system with ultra-low linear thermal expansion

- LED Illumination with interchangeable objectives to achieve high accuracy / high magnification measurements

- Includes real-time temperature compensation

- Includes pattern focus optical enhancement hardware to measure translucent and reflective parts

ULTRA QV (0,25 μm)

- Ultra-high Accuracy CNC Vision Measuring System

- High accuracy of 0,25 μm

- Minimize straightness errors with precision air-bearing linear guide system

- Scale resolution of 0,01 μm scale system with ultra-low linear thermal expansion

- Halogen lighting with 3X magnification turret and interchangeable objectives

- Includes real-time temperature compensation

- Includes pattern focus optical enhancement hardware to measure translucent and reflective parts

QVPAK software:

Software of enormous versatility and ease of use for the entire range of QUICK VISION measurement systems. Its excellent graphic representation on the screen opens a new horizon in terms of efficient measurement.

With QVPAK, even extremely complex measurement processes can be easily planned, controlled and evaluated. Even new users will have a smooth adaptation in the QPAK environment with its integrated online help. And the QVBasic programming language, which is based on Visual Basic, guarantees maximum flexibility, for example, by connecting barcode readers, transferring data to MS Office applications or creating user-defined input and query dialogs.

Related products and services

With this system you can use different softwares depending on your needs and uses. We will always advise you about the most appropriate complement for your company if you wish. Do not hesitate to ask us.

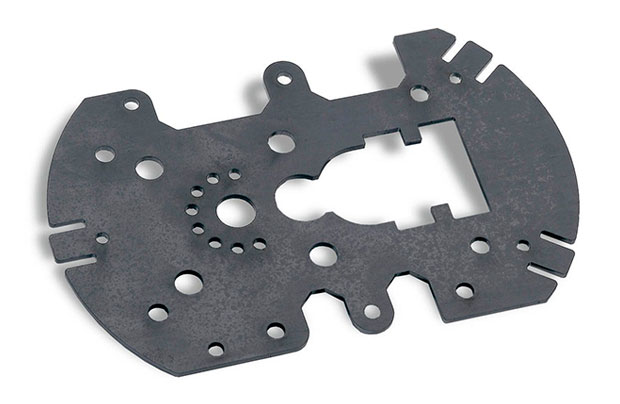

Applications

Precision turned parts, spring, electronics industry, high precision machining, plastic injection, aluminum profile, perforated and folded parts, parts by laser cutting ... etc

Custom solution

Our engineering department can customize and integrate any Quick Vision measuring machine according to your requirements. Tell us what your challenge is and Sariki will advise you to identify which is the best solution for your specific case.

LOADING SYSTEM

You can incorporate manual, semi-automatic and automatic loading systems into the equipment

CABIN SYSTEM

We identify the cabin system that best suits your application

INTERACTION WITH PRODUCTION MANAGEMENT SYSTEMS

We guarantee 100% traceability of the process by integrating the CMM data with your MES/ERP system

CUSTOM PROGAMMING

We have experienced staff in programming and measurement for the realization and implementation of measurement part-programs

TURNKEY PROJECT

If you are looking for a turnkey project you can trust on us. We work with you from the conception of the idea and definition of project conditions, prior acceptance, installation in your company, user training and technical assistance and support throughout the life of the project.

We face integration projects from a holistic view of inspection guidelines and are committed to comply hybridization technologies. We can develop an inspection solution that combines different technologies: three-dimensional machine, roughness, vision, etc.

Technical specifications

Accuracy

from 2 μm to 0,25 μm