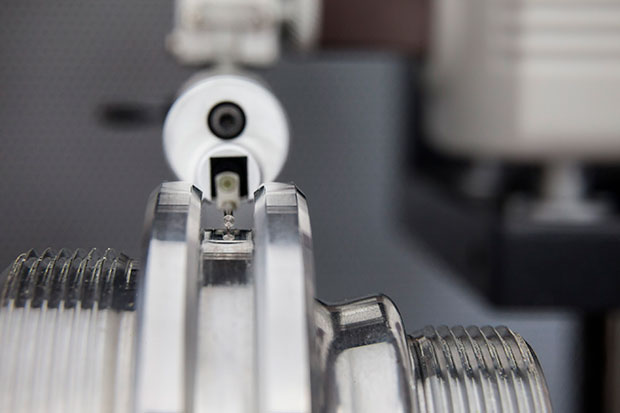

Individual sensor

Mitutoyo FTA-D3000 and FTA-D4000 models are systems that perform two separate measurement sequences to obtain the roughness and profile of your parts in a single software to obtain the best performance of each of the technologies.

FTA-D3000: Intelligent combination of two complete systems for contour measurement and comprehensive surface analysis.

- Two separate, interchangeable sensors

- Digital scale

- Motor-driven height-adjustment of the Z axis

- Fully-automatic sequence of measuring programs

FTA-D4000: For particularly stringent requirements in contour measurement in the measuring room and laboratory. With dual stylus system for upward/downward contour measurement.

- Two separate, interchangeable sensors

- Dual stylus contour measuring unit

- Motor-driven height adjustment of the Z axis

- Fully automatic sequence of measuring programs

All devices use Mitutoyo Formtracepak software. It is a complete profile and surface measurement program of maximum efficiency with versatile evaluation and documentation options.

Automatic sequences of the measurement program

Bestfit function for automatic measurement sequence

Representation of graphic and numerical results

Graphical representation of the outline of the profile or surface profile

Construction of help geometries

Profile comparison

Freely definable tolerance ranges

Edit function

Automatic storage of measurement results

Automatic calibration function

Calibration data file

Related Products and Services

With this system you can use different softwares depending on your needs and uses. We will always advise you about the most appropriate complement for your company if you wish. Do not hesitate to ask us.

Applications

Profile measurement on any part (machined or not) avoiding in most cases the need to destroy the sample to ensure access. Measurement of internal profiles, measurement of threads, bevels, etc.

High precision measurement and analysis of any surface. The 3D measurement opens up new possibilities for the analysis of new materials and new surfaces derived from the new manufacturing processes (additive manufacturing, etc ...).

Custom solution

We accompany you throughout the life of the project: definition of the project, installation, training, programming, user support, software updates, technical assistance, calibration and maintenance.

We can offer you solutions to automate and integrate your roughness and contour measuring instrument easily

Technical specifications

FTA- D3000

Traverse

Z2 300mm/500mm/700mm

Measuring range

X 100/200mm; profile Z1 60mm; roughness Z1 800 µm, 80 µm, 8 µm

Measuring speed

0,02-30 mm/s

FTA- D4000

Traverse

Z2 300mm/500mm/700mm

Measuring range

X 100/200mm; profile Z1 60mm; roughness Z1 800 µm, 80 µm, 8 µm

Measuring speed

0,02-30 mm/s