Fagor Ederlan

Fagor Ederlan incorporates metrological equipment to its production lines, emphasizing the demanding precision specifications of the manufactured components.

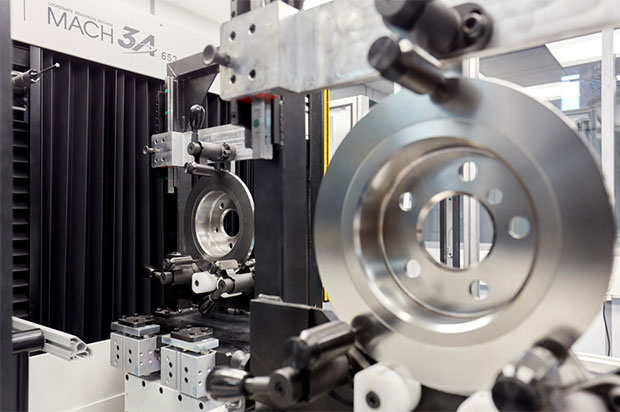

Tecnology: Mach 3A

Sector: Automotive

Sariki and Fagor Ederlan, a growing collaboration

The beginning of the relationship between Fagor Ederlan and Metrología Sariki dates back to the early 90s. From 2006 on, the business relationship was reinforced with different projects for the chassis components that Fagor Ederlan designs and manufactures for the automotive sector.

Fagor Ederlan is a specialist supplier in the manufacture of safety components for this sector. These components, therefore, are of great complexity and demand. The initial challenge posed by the cooperative required the incorporation of metrological equipment to its production lines, guaranteeing the demanding precision specifications of the manufactured components.

The universal solution should enable the removal of specific inspection tools, the coexistence with the productive environment, the simplicity to be used by the machine operators themselves and real-time results information for a more dynamic and efficient control of the manufacturing process.

The first implementation of this type of project was carried out in 2007, with a solution consisting of a three-dimensional measurement system Mitutoyo MACH V 9106 equipped with sensors, dual pallet for part loading and an application with a simple interface for users of the plant, in addition to the monitoring through the statistical control of the process. The solution guarantees control of specifications at micron level, even with temperature variations.

Throughout these years and keeping a very close relationship with Fagor Ederlan, we have been permanently improving every solution, currently with machines in all its machining plants.

The relationship between both companies extends to other subcontracting and training activities, but the agreement to perform a maintenance and calibration of all the machines is especially relevant.

About Fagor Ederlan Group

The Fagor Ederlan group is a leading supplier of automotive components focused on the Chassis and Powertrain functions of the vehicle. It offers integral solutions to the market in all the product lines, counting with the main manufacturers of vehicles and Tier 1 suppliers as a customer. This allows them to share, understand and reach the most relevant market challenges, giving a personalized response to the current and future needs of each client and region of the market.

Its clear service vocation has led the group's international growth, turning Fagor Ederlan into a global supplier with 18 plants in the main regions of the sector such as Europe, Mercosur, Asia and North America.

With more than 4,500 professionals and more than 1800 members, it is the largest cooperative in number of members of the MONDRAGON Corporation industrial group, and the commitment to generate cooperative employment and working with the environment continues to be the key to its strategy.