In process weld measurement

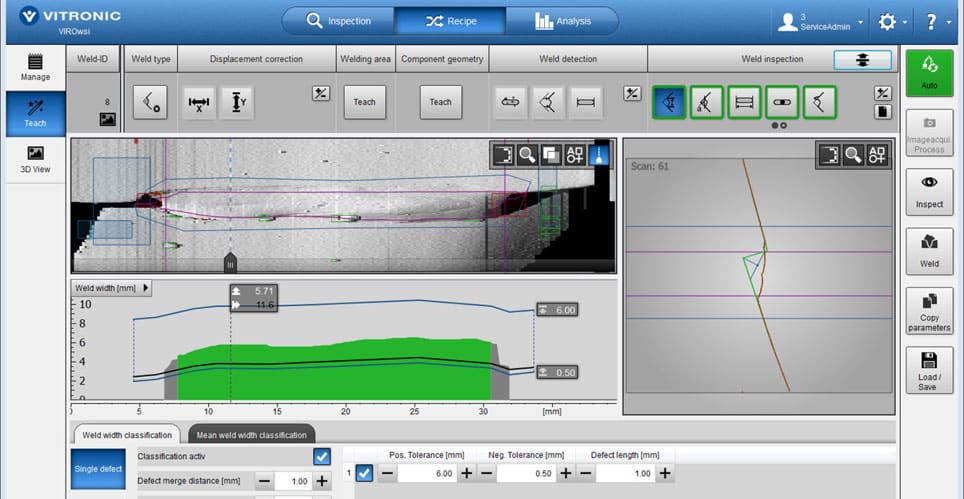

We propose the VIRO WSI solution for in process weld measurement.

The weld seams of the bodies in automotive sector can be inspected using laser scanning technology in the production plant.

Sariki is the official distributor of VITRONIC for Spain and Portugal

Triangulation laser scanning technology for in process weld measurement

Weld seam inspection is a crucial process in car body manufacturing, as it ensures that the quality of the weld meets the standards required to guarantee the safety and durability of the vehicle.

Nowadays, every process of the productive value chain requires to be verified to ensure the optimum quality of your products. That is the reason why industrial robots are executing a very important role, automating measurement tasks in the production line.

Sariki proposes a new solution that combines the laser scanning technology connected to a multi axle robot that provides you with a fast and precise measurement for the weld beads of your productive process. Weld seam inspection reliably detects all welding defects in the car body – on both visible and invisible seams. Even the slightest defects are detected – immediately after the welding process. This means that corrective actions can be swiftly implemented.

VITRONIC uses laser triangulation technology. This allows laser seams and fine brazed seams to be inspected quickly and with high resolution in 3D. Seam detection presents a particular challenge with flat car body seams. VIRO WSI clearly identifies the tiniest geometric and cosmetic deviations.

Inspection range (a selection):

- porosity

- weld width

- seam interruption

Every Inspection Means Process Optimization

The VIRO WSI inspection system from VITRONIC stores the results of all seam and component inspections in an integrated database. From this data, you can immediately determine any action that may be required. In addition, your growing database enables you to initiate effective long-term optimizations and implement these on an ongoing basis. A single imperfect roof seam can render an entire car body unsellable– but this is a cost that can be avoided! Weld seam inspection ensures that only perfectly welded car bodies leave your production line. This, in turn, guarantees optimal customer satisfaction and protects your brand image.

Benefits

Scan and compare against CAD

Get superficial values: width, height, area, volume, holes, weld bead’s position, etc.

Measure 100% welds

Achieve measurement results in real time

Take decisions faster

Optimize processes

Improve productivity

Integral project adapted to your needs

We offer an integral solution, adapted to your needs. The experience tells us that the collaboration with the client is the basis of success in this type of projects and that is the reason why we work jointly from the beginning, to identify which are the principal requirements and suggest the best solution.

We accompany you throughout the life of the project: project definition, installation, training, programming, user support and technical assistance. Sariki is made up of 60 highly specialized people with more than 35 years of experience in the metrology sector.