In process defect inspection

We suggest a solution based on vision technology for in process defects’ inspection.

By means of this technology you would be able to carry out the superficial analysis of all your production, with fast and accurate measurements, fulfilling all the requirements of the most leading sectors as the automotive one and aeronautics.

Solution developed by Sariki

In process defects’ inspection technology

Maintaining the high quality of your products in face of the technological developments of the 4.0 industry involves putting more emphasis in the automation, connectivity, data transparency and usability. Sariki accompanies you to reach these objectives of the intelligent manufacturing, based on accurate and effective solutions, easy to use, allowing the adaptation to any variation in your process.

In the smart factory’s infrastructures, the vision as defects’ inspection technology has become an essential element. Due to the accuracy, high strength and reliability, as well as the easiness that offers for the communication and intelligent exchange of information, turns out to be the key technology not only in manufacturing, but also in the quality control.

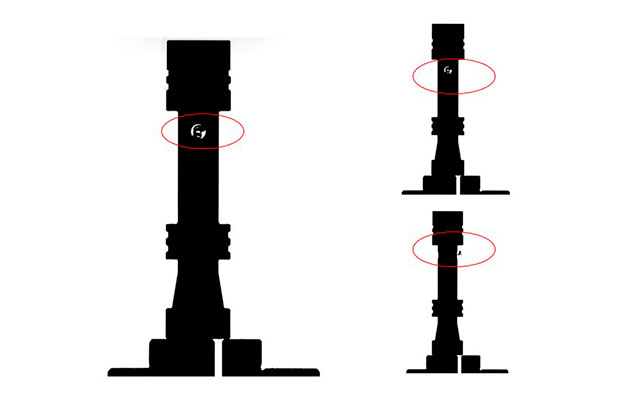

Sariki offers in line vision solutions with which you could make the superficial analysis of all your parts. These solutions are based on stereophotogrammetry, meaning, the technology that uses the photographs taken under controlled conditions, for the tridimensional model construction, based on the positions of the recognizable points or the reference points in those photographs.

These vision solutions are a combination of hardware and software that captures, processes and analyses images, producing information for the decision making. The automated inspection systems that we are offering you, produces point clouds in fast cycles, compiling 3D measurement data during the manufacturing process.

Benefits

Automate your productive plant

Reduce costs

Obtain more information of the inspected part

Decrease error rates

Take decisions faster

Synchronize data in real time

Have traceability of the information

Accelerate inspection time

Control and optimize your processes

Integral project adapted to your needs

We offer an integral solution, adapted to your needs. The experience tells us that the collaboration with the client is the basis of success in this type of projects and that is the reason why we work jointly from the beginning, to identify which are the principal requirements and suggest the best solution.

We accompany you throughout the life of the project: project definition, installation, training, programming, user support and technical assistance. Sariki is made up of 60 highly specialized people with more than 35 years of experience in the metrology sector.

We accompany you throughout the project life

Aplications

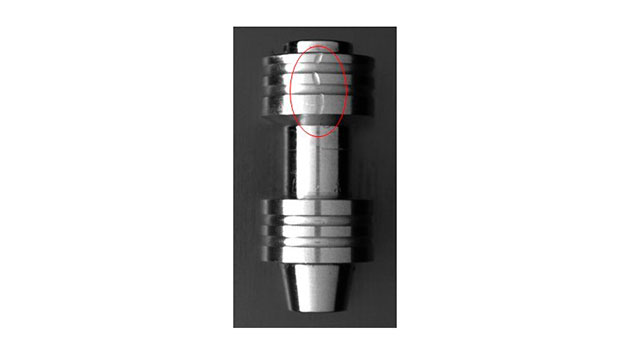

OK / No OK

Part defectology

Lack of material

Errors’ detection