New Mitutoyo MiStar 555 measuring machine for production environments

Mitutoyo has developed an innovative solution for your shop floor measuring tasks.

The MiSTAR 3d measuring machine guarantees high speed and accurate measurements even in severe machining sites without the need to create a special environment in the production area. It offers a guarantee of precision under a wide range of temperatures from 10°C to 40°C and requires only a 100 V AC power supply. The flexibility in its installation and the saving of space have reduced the area of installation to approximately 70 percent of the CMM of conventional bridge type.

Designed to be easily automatable. Mistar 555 uses an open frame design (570 x 500 x 500mm) with an x-axis cantilever type allowing users to easily locate a part for measurement from three directions: the front, back and right side.

It’s a versatile and flexible system. You can incorporate the following probes: TP200 and SP25M

Aplications

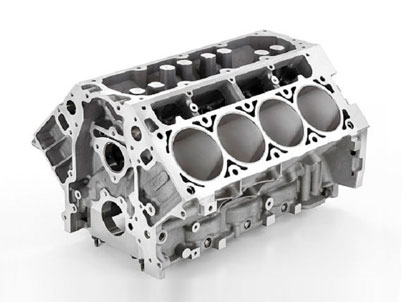

MiSTAR has been designed for high precision inspection of the automotive, aeronautical, health, capital equipment, machine tool, consumer … etc parts directly in production. The equipment is suitable for inspection of machined parts, stamping, plastic / aluminum injection, turbine blades, gears, molds and dies … up to 500mm.

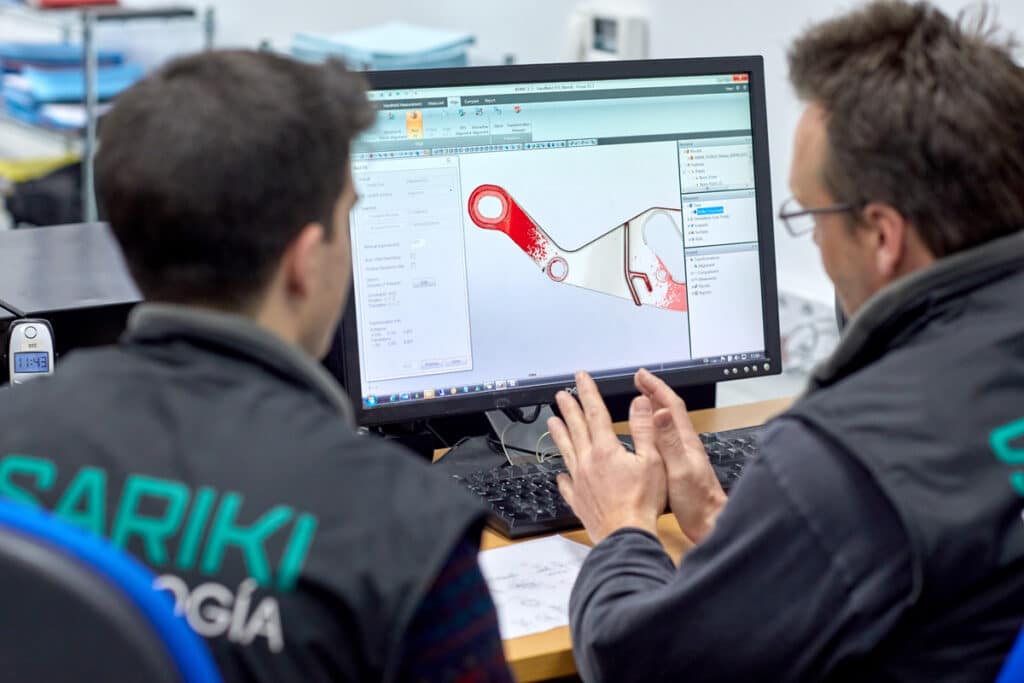

Custom solution SK/solutions

Our engineering department can customize and integrate the MiSTAR 555 coordinate measuring machine according to your requirements. Tell us what your challenge is and Sariki will advise you to identify which is the best solution for your specific case.

- Loading system. You can incorporate manual, semi-automatic and automatic loading systems into the equipment.

- Cabin system. We identify the cabin system that best suits your application.

- Interaction with production management systems. We guarantee 100% traceability of the process by integrating the CMM data with your MES/ERP system.

- Custom programming. We have experienced staff in programming and measurement for the realization and implementation of measurement part-programs.

- Integration in production line. If you are looking for a turnkey project you can trust on us. We work with you from the conception of the idea and definition of project conditions, prior acceptance, installation in your company, user training and technical assistance and support throughout the life of the project.

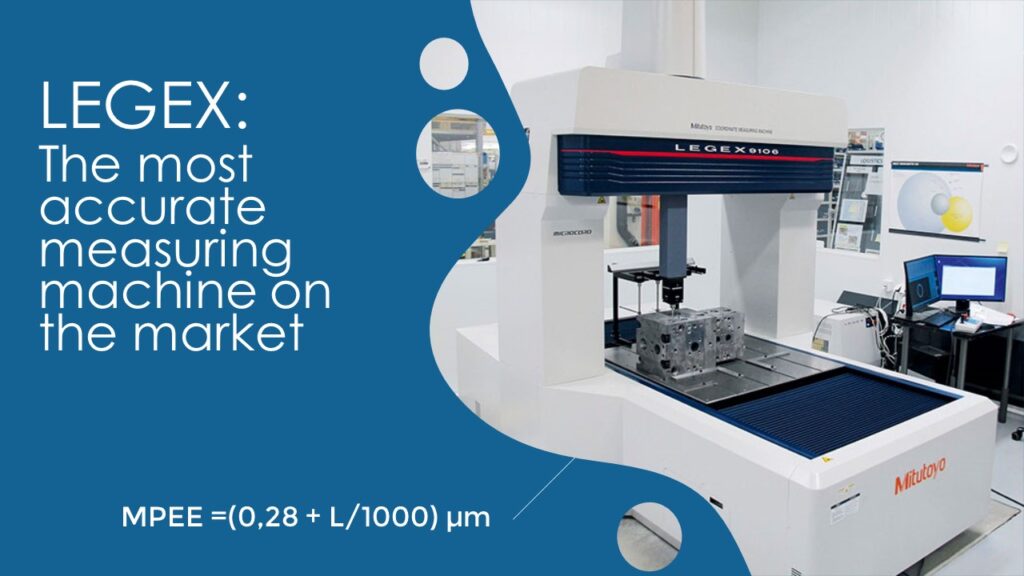

Technical specifications:

- Measuring range X 570mm; Y 500mm; Z 500mm

- Accuracy from (2.2+3L/1000)μm

- 18ºC-22ºC; (2.2+3L/1000)μm

- 10ºC-30ºC; (2,9+4,5L/1000)μm

- 10ºC-40ºC; (3,6+6L/1000)μm

- Resolution 0,0001mm

- Driving speed 606mm/s

- Driving aceleration 2.695 mm/s2

- Temperature range from 10ºC to 40ºC

- Machine mass 655Kg

If you want to receive advice on MiStar 555, fill in the following contact form.